Edge rounding

Better adhesion of the coating and less risk of injury

SBM-XS G1E1

Double sided deburring of small parts - Deburring and uniform edge rounding on all sides of parts, both on outer- and inner contours, in a single pass

SBM-M S2

Deburring and edge rounding of steel and stainless steel on both sides in one single pass

SBM-M D2

Slag removal of plasma and oxy fuel cut parts on both sides in one single pass

SBM-L G1S2

Deburring machine for grinding, deburring and edge rounding of punched, laser and high definition plasma cut parts in one single pass

SBM-L G1S2 EVO

Deburring machine for grinding, deburring and edge rounding of punched, laser and high definition plasma cut parts in one single pass

SBM-XL G2S2

Deburring and edge rounding of laser, plasma and oxy fuel cut parts on both sides in one single pass

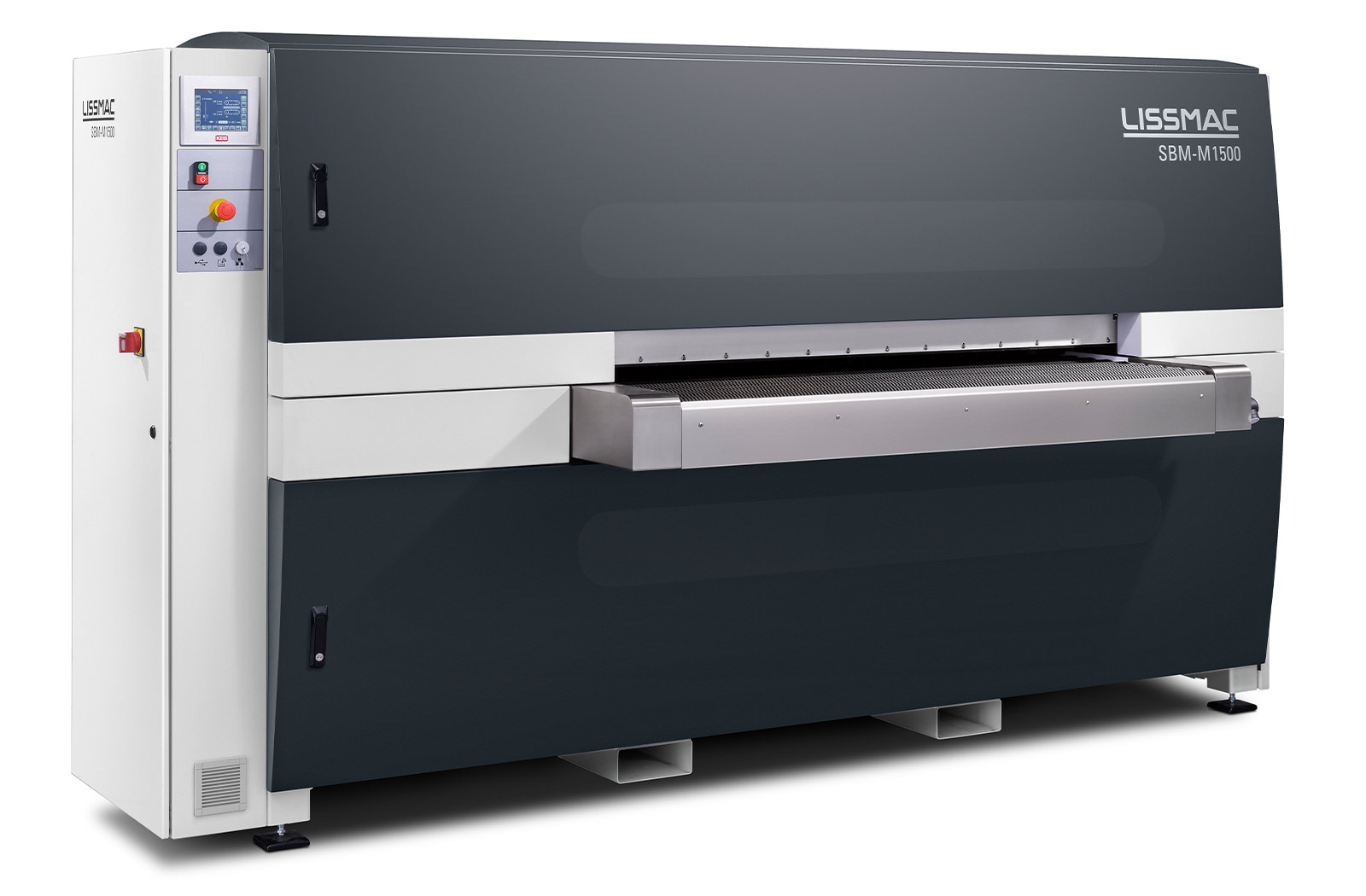

SMD 123 RE

Dry grinding machine for deburring, consistent edge rounding and surface finishing

SMD 133 DRE

Economical removal of slag, deburring and edge rounding on plasma- and oxy-fuel cut parts

SMD 3 S - EDITION

Outstanding results on the edge and on surface

SMD 3 P - EDITION

Highest-end edge rounding

SMW 5

Grinding machine in wet execution for the perfect surface finish

Why rounding sharp edges is Critical for US Manufacturers

In modern American metalworking industries, precision, worker protection, and surface quality are critical. Cutting, punching, or laser processing of sheet metal inevitably creates sharp edges and burrs. These not only present a significant risk of injury but also reduce the effectiveness of paints and powder coatings.

This is where edge rounding becomes essential.

Also known as edge breaking, edge rounding is the controlled process of removing burrs through the deburring process and creating uniform, defined rounded edges on all sides of a workpiece. By ensuring consistent edge geometry, edge rounding enhances coating adhesion, improves product durability, and helps meet today’s demanding quality standards in surface finishing and downstream processing.

How Edge Rounding Works – The Process Explained for US Fabricators

1. Workpiece Transport – Foundation for Precision

To achieve consistent and high-quality edge rounding, metal parts must be securely guided through the machines. Depending on the part size, shape, and material, LISSMAC edge rounding machines are equipped with specialized transport systems:

PowerGrip Conveyor Belt – ideal for small or embossed metal parts, highly energy efficient and versatile

Vacuum Table – suited for large, sensitive metal sheets requiring careful handling

Magnetic Track – delivers strong holding force for ferromagnetic steel components

These transport systems ensure stable positioning of metal parts, allowing precise and accurate processing on every pass.

2. Preprocessing

Before edge rounding begins, burrs must be removed in the deburring stage using longitudinal or wide-strip machines. Slag and oxide layers are carefully removed with PowerPins and brush strips. This prevents secondary burrs that can compromise surface quality and downstream performance.

3. Edge Rounding - edge radius of 0,08" (2mm)

The actual rounding step produces rounded edges up to a radius of 0,08" (2 mm). Depending on production requirements, sanding belts or flap brushes are used:

- Sanding belts – for strong, uniform rounding across larger surfaces

- Flap brushes – for precision, especially suited to complex contours

This creates smooth, high-quality edges with enhanced surface durability. The result: improved coating adhesion, longer product life, reliable performance, and a safer tactile feel.

Typical US Applications for Edge Rounding

Edge rounding is essential wherever precision and finish quality matter, including:

- Laser-cut stainless steel, steel, or aluminum sheets

- Punched or plasma-cut parts

- Inner and outer contours, as well as boreholes

- Foiled parts

For example, sharp-edged aluminum components used in electrical enclosures can easily damage protective gloves during assembly. Edge rounding eliminates this risk, ensuring both safety and consistent part quality.

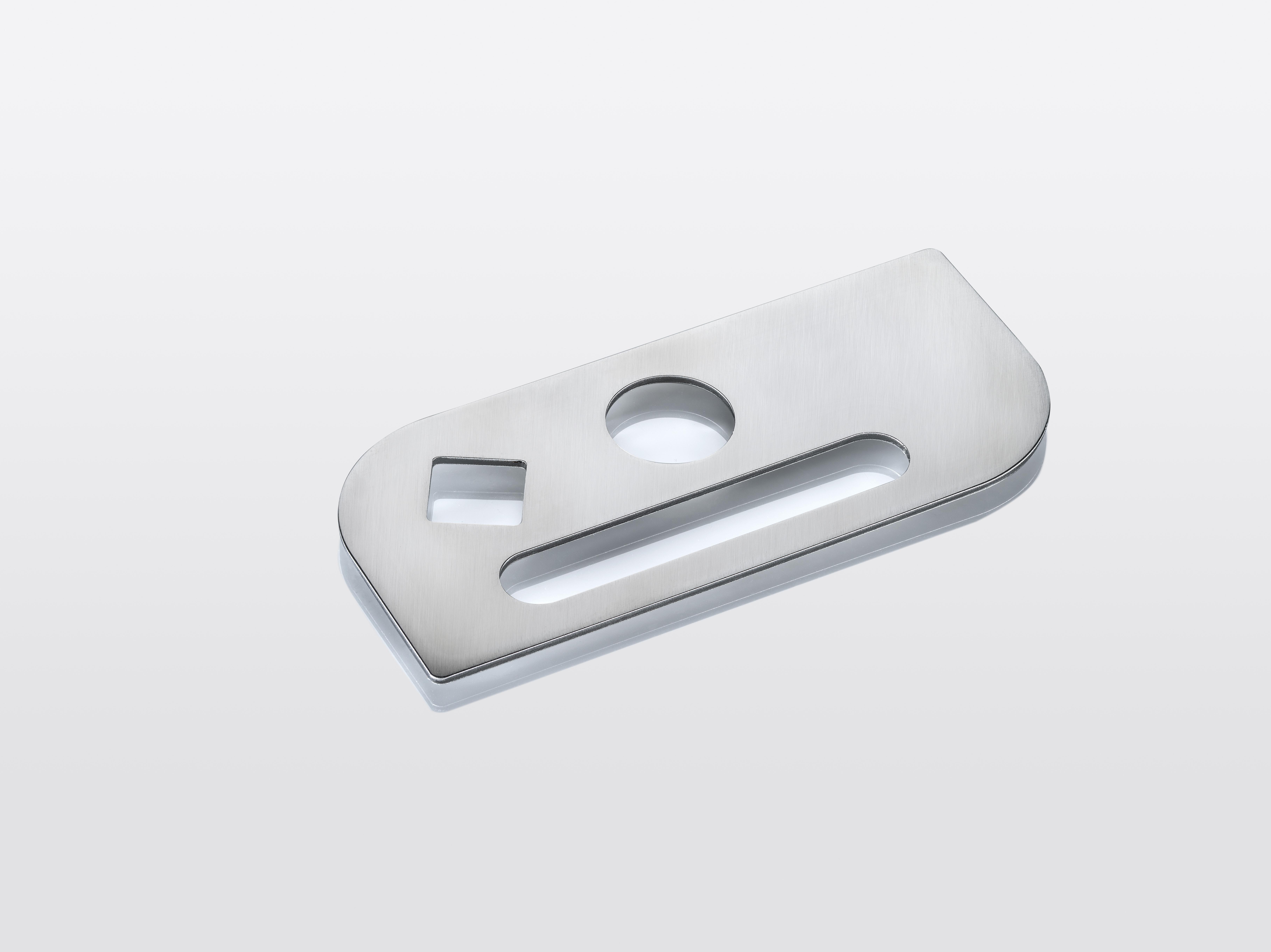

Sheet metal with edge rounding on both sides, processed on a LISSMAC SBM-M S2. The machine removes burrs and ensures uniform rounding of both internal and external contours.

How Optimal Edge Rounding Creates Perfectly Rounded Edges – Why LISSMAC Makes the Difference

The LISSMAC SMD 3 Series stands out with its innovative overlapping rotational systems. These guarantee that sheet metal components are evenly rounded on every side, independent of geometry or material. Processing widths range from 12" (300 mm) up to 78” (2000 mm), delivering consistent results across the board.

The benefits are clear:

- Improved corrosion protection through superior coating adhesion

- Enhanced product safety and durability

- Significantly reduced injury risk from sharp edges

- Smooth, reliable surfaces resistant to rust and oxidation

For U.S. operations, machines are designed for 480 V, 60 Hz, 3 PN+N connection.

Preventative Maintenance and Service Support in the USA

PM Plans Available

Preventative Maintenance Plans from LISSMAC ensure your equipment investment performs at peak efficiency for many years. While maintaining and servicing our machines is straightforward, many customers take advantage of our expert service through personalized PM packages.

- Our expansive U.S. parts inventory in stock is ready for immediate shipment to our customers from within the United States.

- All machines are protected by a standard warranty, which can be extended when combined with our PM Plans.

- This support keeps downtime to a minimum and ensures maximum return on your equipment investment.

Easy Operation – Fast Employee Onboarding

LISSMAC machines are built with a user-friendly operating concept. This makes it easy to train and onboard new team members quickly and efficiently, reducing learning curves and ensuring consistent, safe operation from day one.

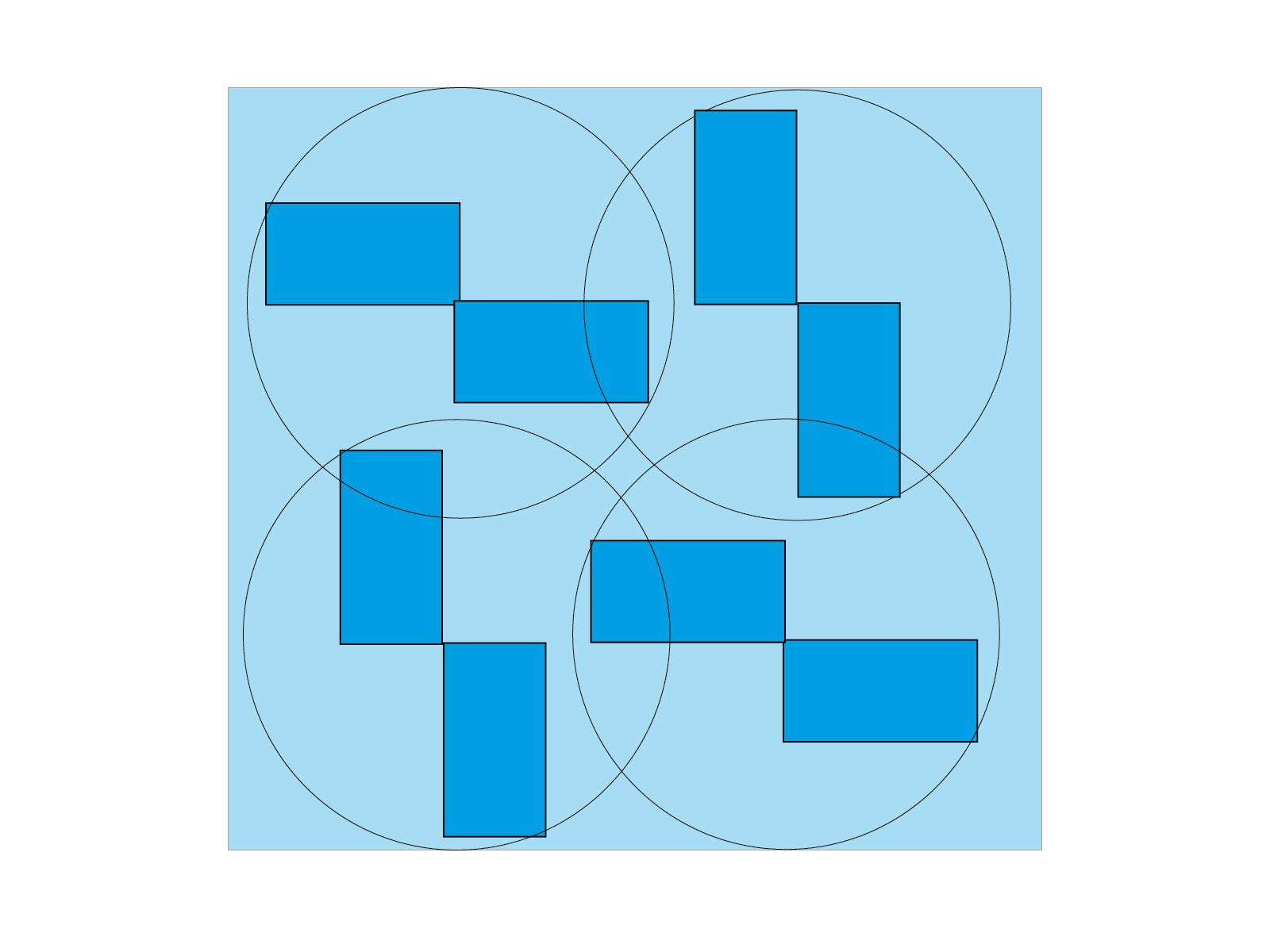

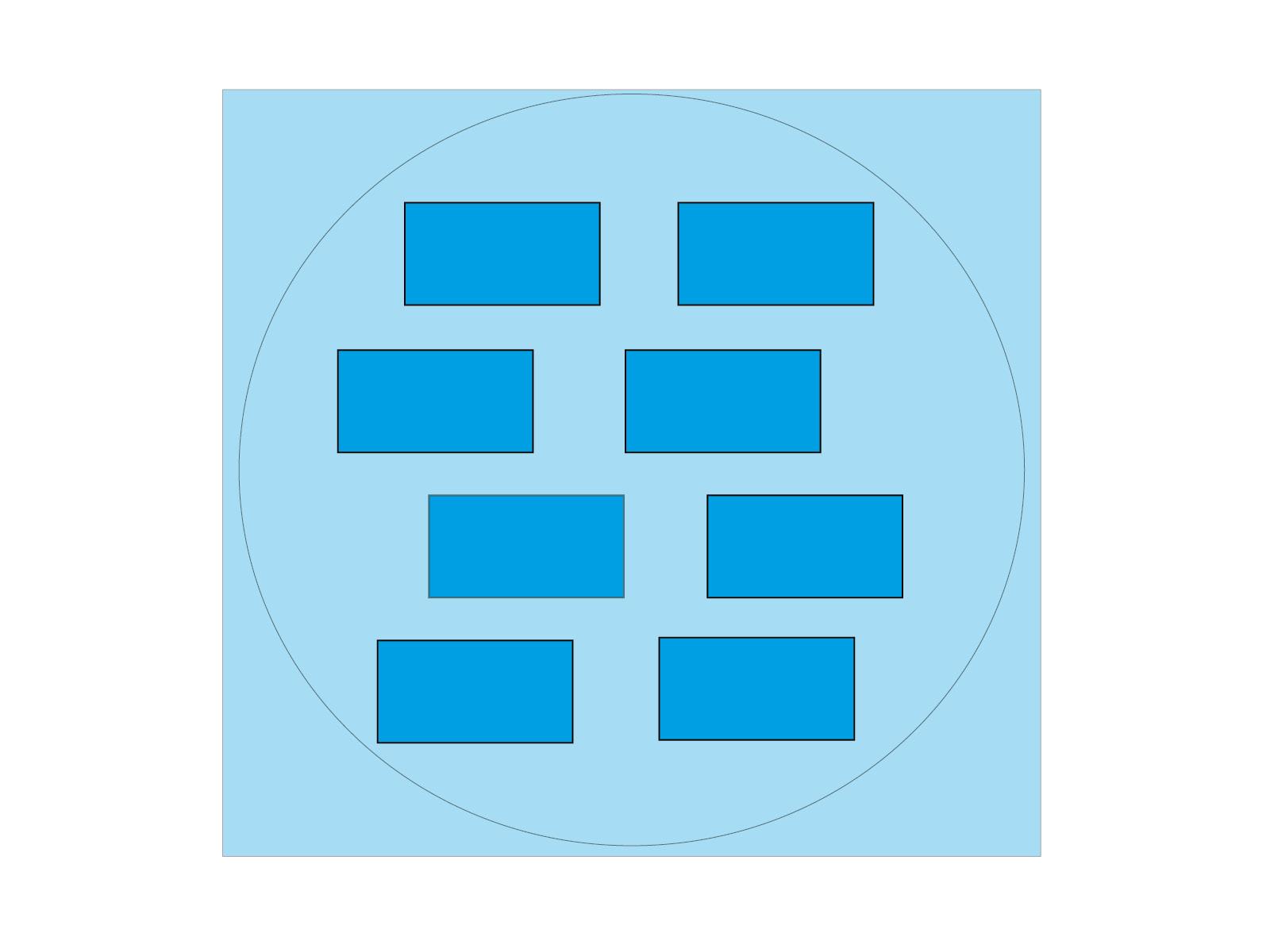

On the left side of the image, you can see the LISSMAC rotation system – equipped with four overlapping, rotating brush heads that ensure consistent, high-quality results. The system shown on the right, on the other hand, works with several brushes that rotate around a central axis. This can result in less rounding at the edges of the conveyor belt, while stronger rounding occurs under the central axis.