SMW 5

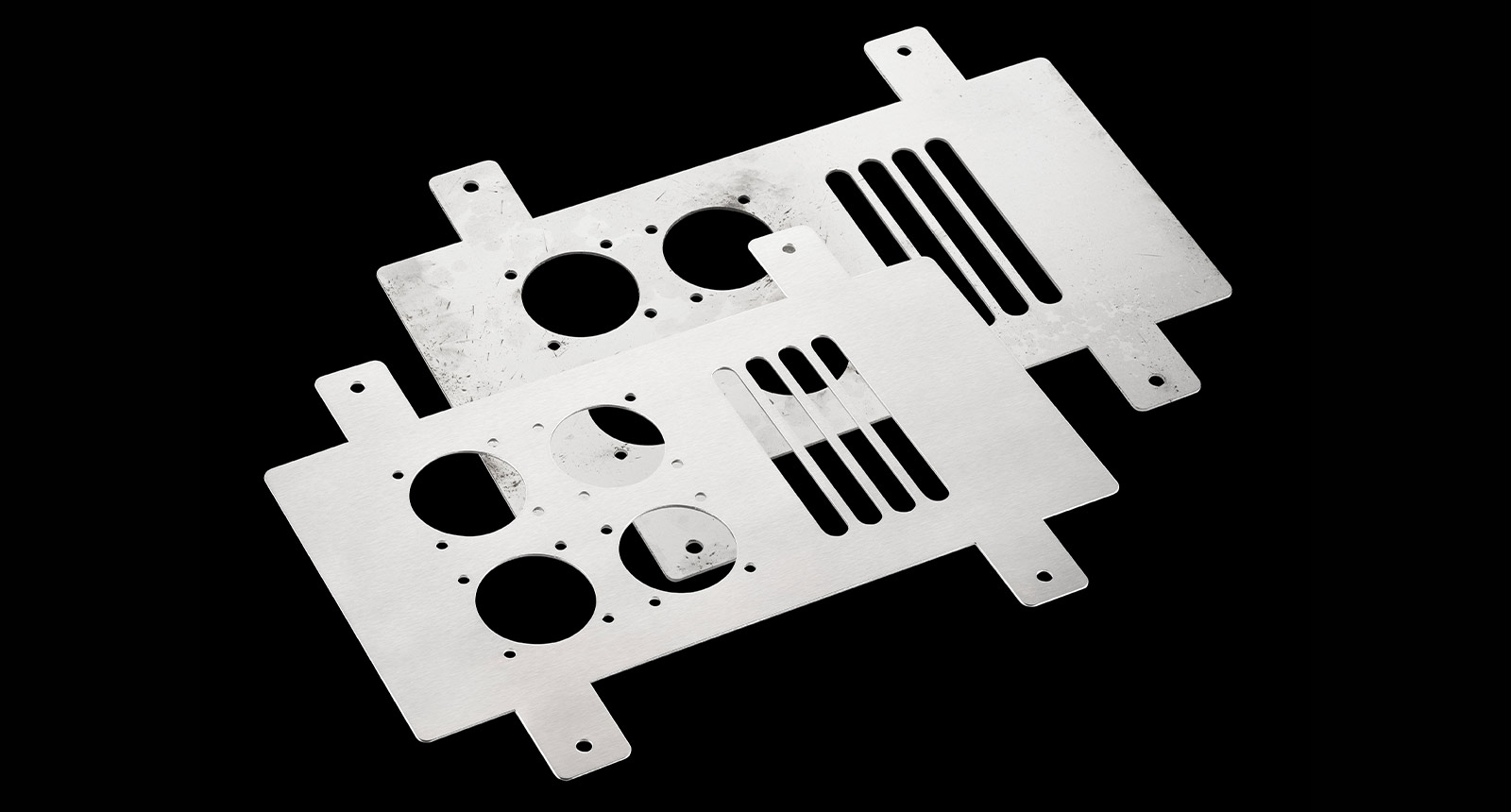

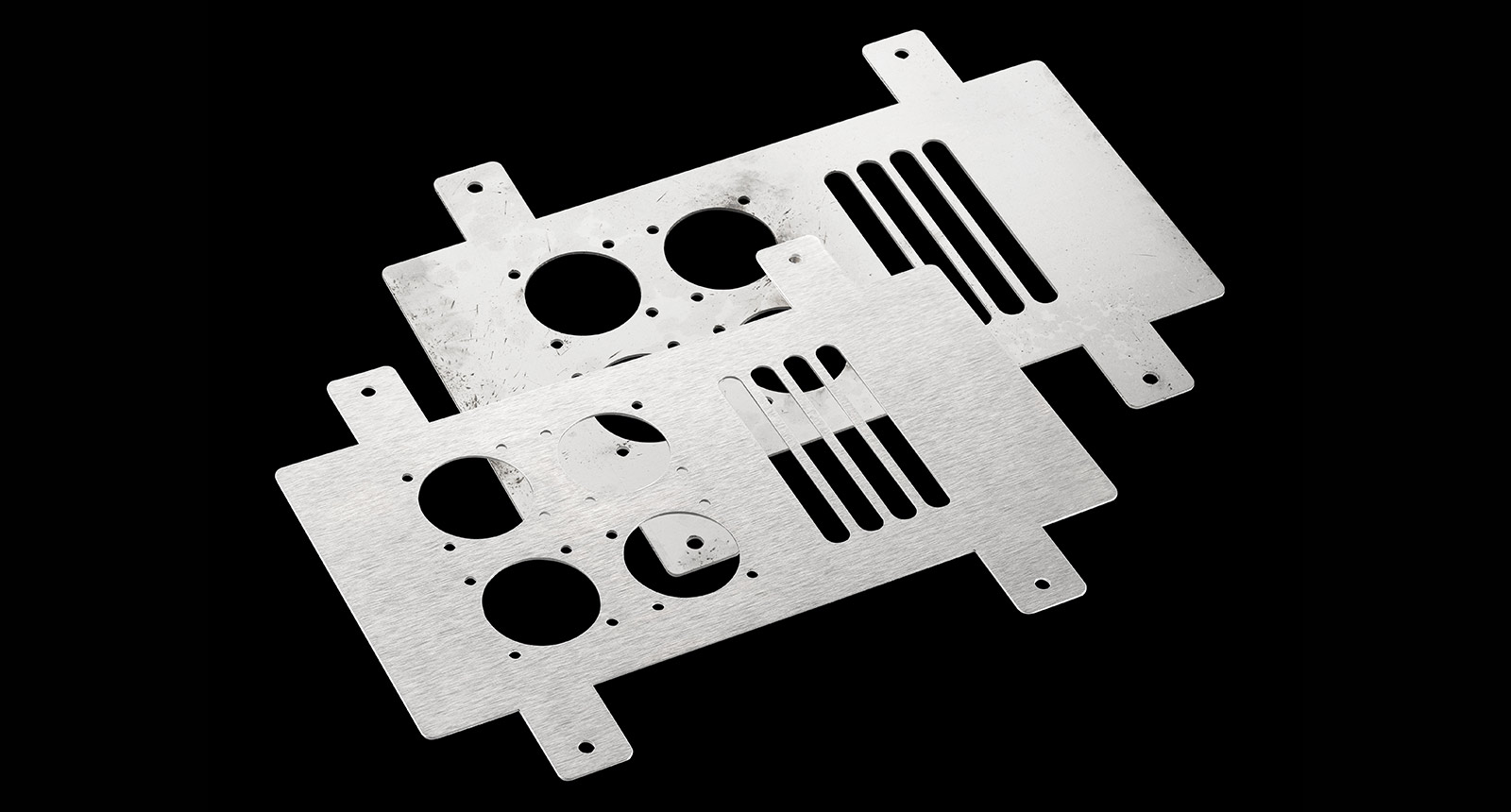

The high-end solution can be used for wet grinding of any sheet metal parts, laser parts and stamped parts as well as for a high-end surface finish.

The LISSMAC SMW 5 series grinding machines ensure optimal surface grinding and a unique high-end finish using the wet grinding process. The grinding and deburring machines are not only used for sheet metal deburring and edge rounding. Oily components can also be processed and a decorative finish can be created.

The high-end solution can be used for wet grinding of all sheet metal parts, laser parts and stamped parts. Stainless steel, steel, aluminum and non-ferrous metals can all be processed.

The SMW 5, built on the modular principle, can be configured individually and tailored to the customer‘s requirements. The machines are characterized by low tool costs, easy handling and an economical price-performance ratio.

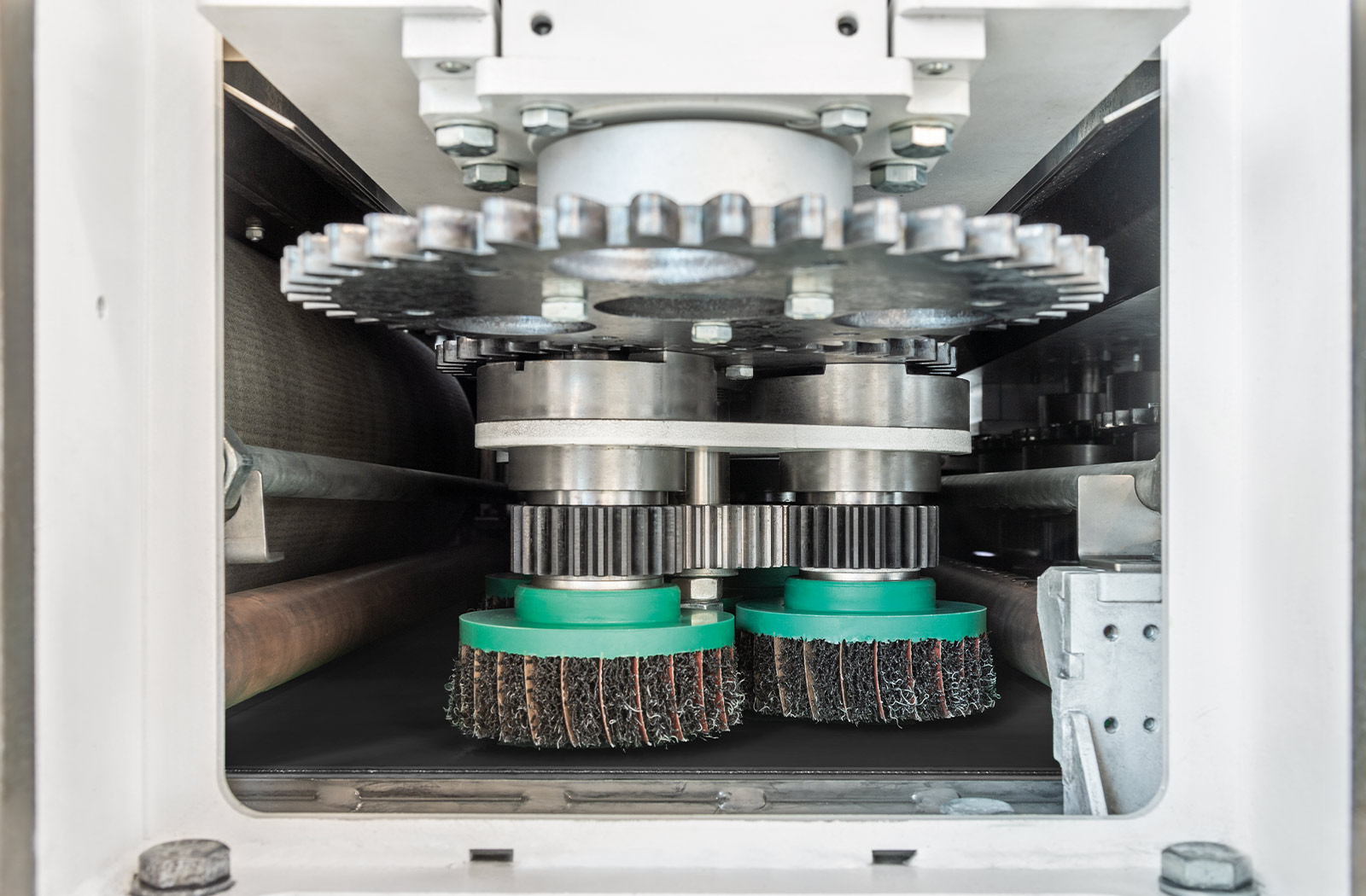

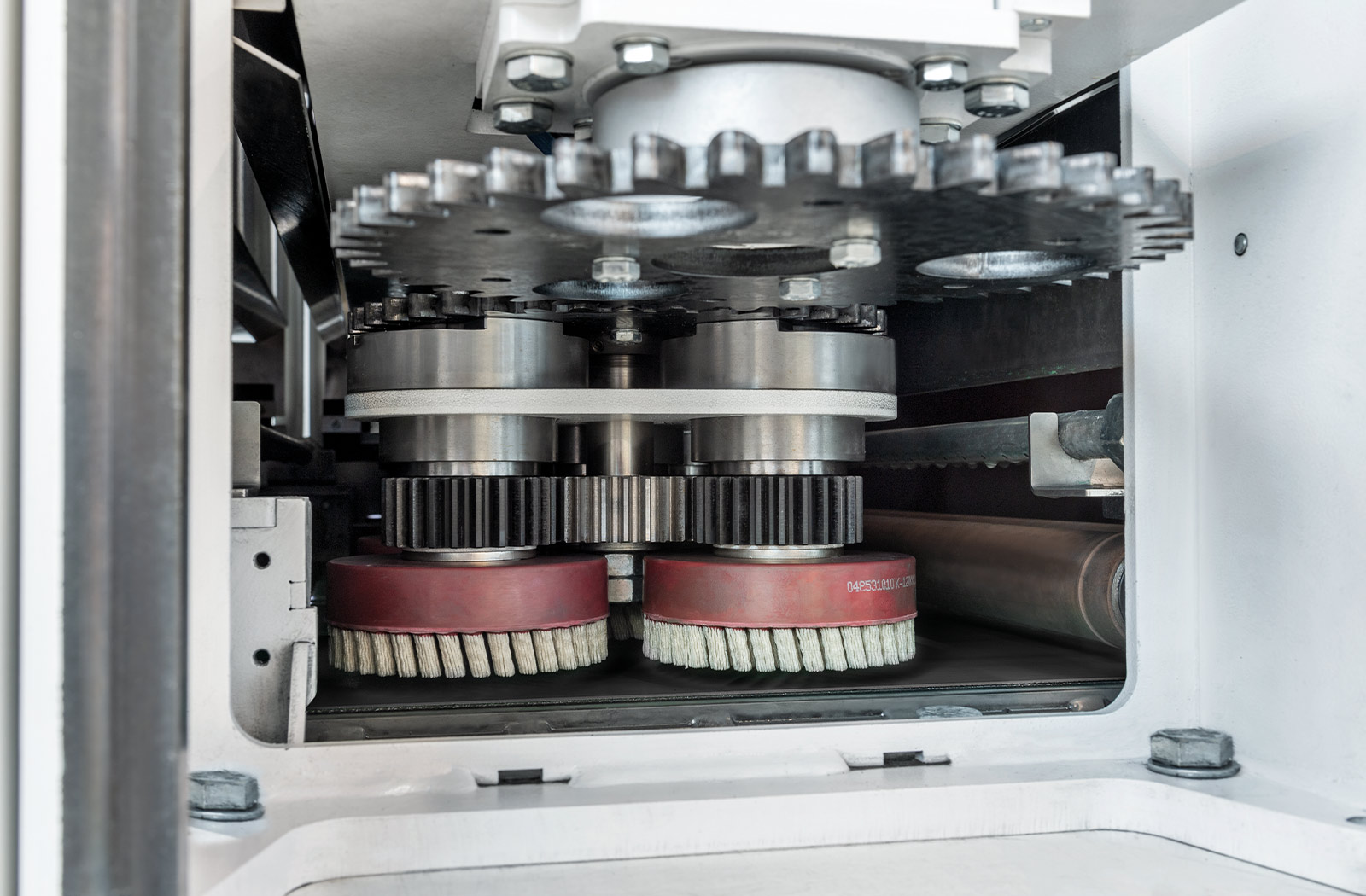

A planetary head unit ensures quality edge rounding and even wear. The wet process guarantees the safe processing of potentially explosive materials. In addition, there is no heat input into the workpieces. And last but not least, the SMW 5 series, which was developed for processing sheet metal up to 120 mm thick, impresses with its short set-up times for the material mix.

Technical data

(37 / 53 / 65 inch)

Further information

- Surface machining or deburring of workpieces up to 120 mm sheet metal thickness

- Freely configurable – individually customised to the customer's requirement

- High quality surface finish up to fine grinding

- Simultaneous deburring of interior and exterior contours

- Wet machining

- Simple, intuitive operation

- The processing units can be individually adjusted or turned on and off electrically.

- Maximum productivity while maintaining machining quality

- Faster and simpler tool change within just a few minutes

- Modular and compact in modern machine design - smaller footprint

- Improved work environment - Reduction of dust, dirt and noise

- Optionally available: Conveyor Technology, Filter Technology; Handling Systems, Automation; Custom Solutions

- Especially suitable for the material mix

- Entire process lines – Grinding and Part Cleaning

Downloads

Examples