Reliably remove burrs

and oxide layers

on plate material

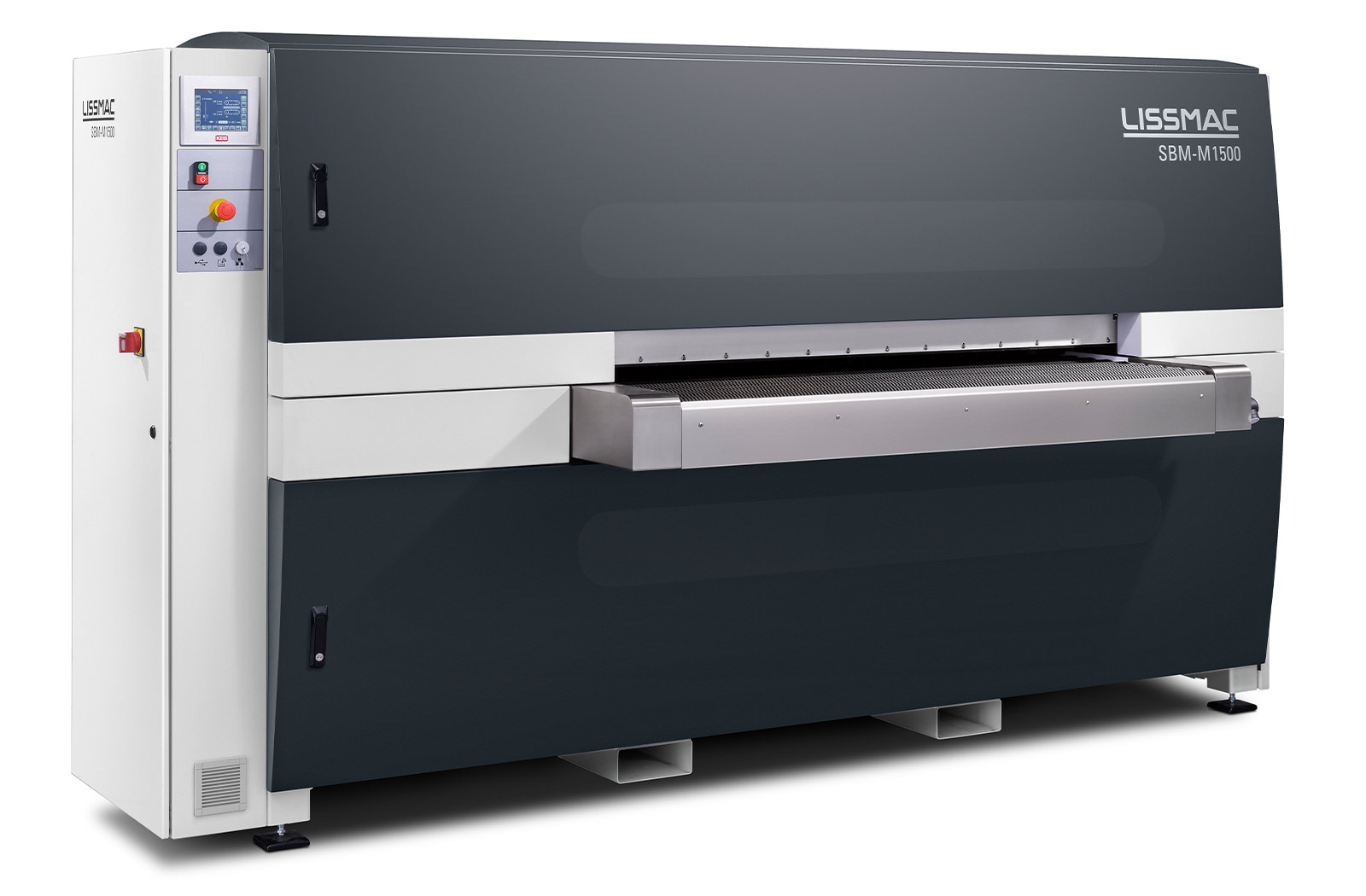

Plate material is often processed by means of plasma cutting or flame cutting. This creates stubborn cutting burrs. Individually adapted deburring machines support the processing of plate material. Deburring rollers followed by brush units are used for this. These reliably remove the burr from plasma or flame-cut parts and then round the edges. In addition to the burrs, slag is also formed during flame cutting, which can be removed with a slag hammer. LISSMAC’s SBM series grinding machines are designed for processing plate material in a single pass. This saves turning over heavy material.

SBM-M D2

Slag removal of plasma and oxy fuel cut parts on both sides in one single pass

SBM-XL G2S2

Deburring and edge rounding of laser, plasma and oxy fuel cut parts on both sides in one single pass

SMD 133 DRE

Economical removal of slag, deburring and edge rounding on plasma- and oxy-fuel cut parts

SMD 3 P - EDITION

Highest-end edge rounding