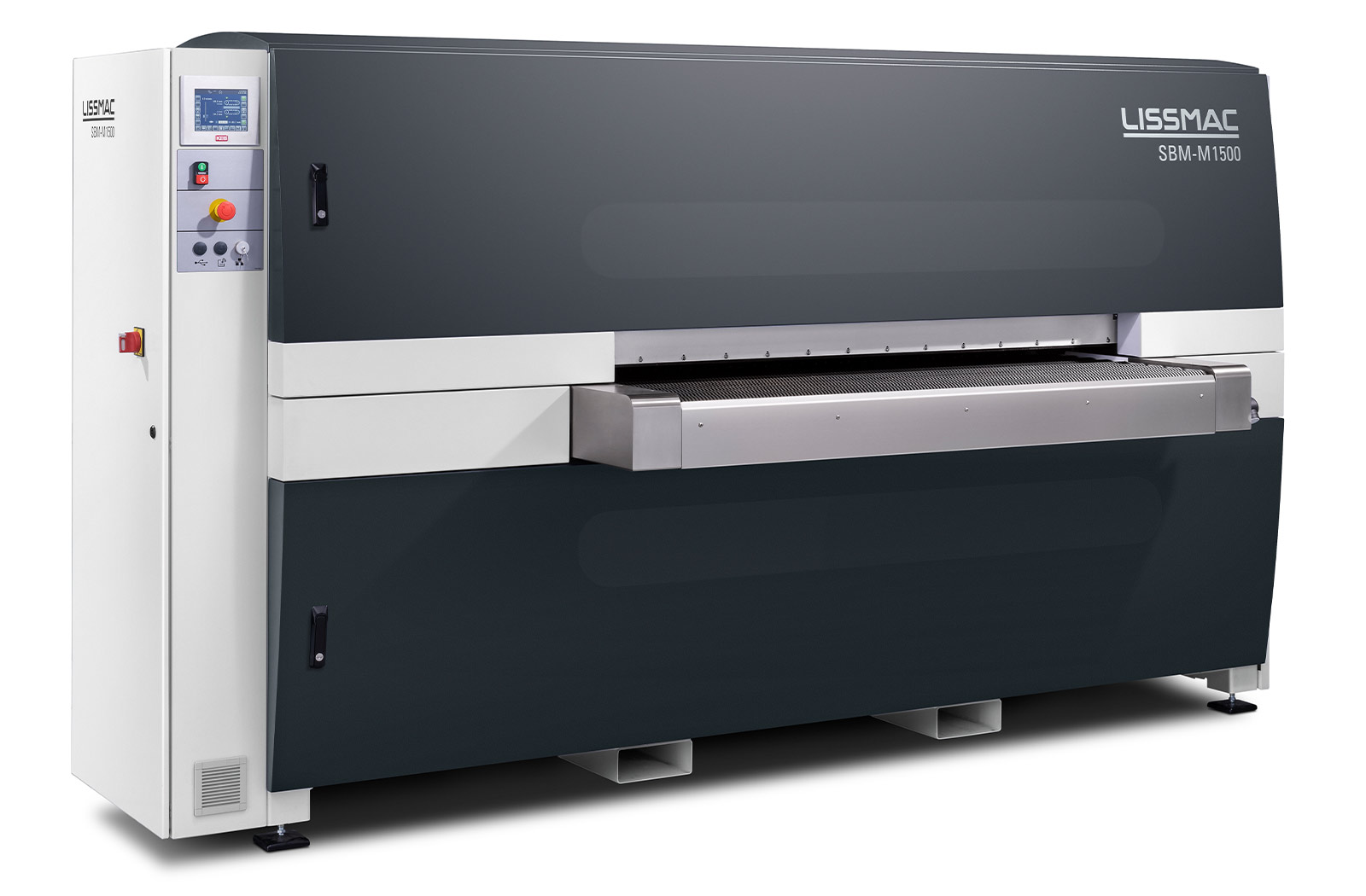

SBM-M D2

The mechanical chipping off of slag with the slag hammer saves costly machining.

The SBM-M D2 grinding and deburring machine was developed for the mechanical removal of slag on both sides of plate material parts. It is ideal for machining plasma and flame-cut parts after oxy-fuel and plasma cutting. The mechanical chipping off of the slag with the slag hammer saves costly machining operations. The SBM-M D2 works on both sides when deburring sheet metal or when removing slag, saving the time an effort of turning over heavy components. The LISSMAC machine concept guarantees optimal ergonomics and makes work easier thanks to its machine processes. The deburring machines can be linked with other LISSMAC machines.

The grinding units work across the workpiece to ensure a long service life and reduced tool costs.

Contact salesTechnical data

(5070 lbs)

(123/56/71 inch)

Further information

- Double-sided slag removal of plasma and thermal cut sheets or plates up to 120 mm

- Saving of tool costs incurred by mechanical deslagging –no time-consuming and expensive grinding

- Double-sided slag removal saves the time intensive turning of the often very heavy workpieces or machining of parts twice

- Up to 60 % work time savings compared to single-sided processing machines

- Modular and compact in modern machine design - smaller footprint

- Dry operation

- The cross-machining principle guarantees uniform tool utilization over the entire working width.

- Upper and lower assemblies separated can be adjusted or turned on and off electrically

- Innovative tooling and material feed system allows for optimum handling of burrs and uneven surface of pieces

- Maximum productivity while maintaining machining quality

Improved work environment - Reduction of dust, dirt and noise - Optionally available: Conveyor Systems; Material Handling; Robotics & Automation; Processing Tools

Downloads

Examples