SMD 133 DRE

The grinding and deburring machine, which has a robust, long-life conveyor belt for heavy workpieces, is suitable for mechanical slag removal and edge rounding on thick sheet metal.

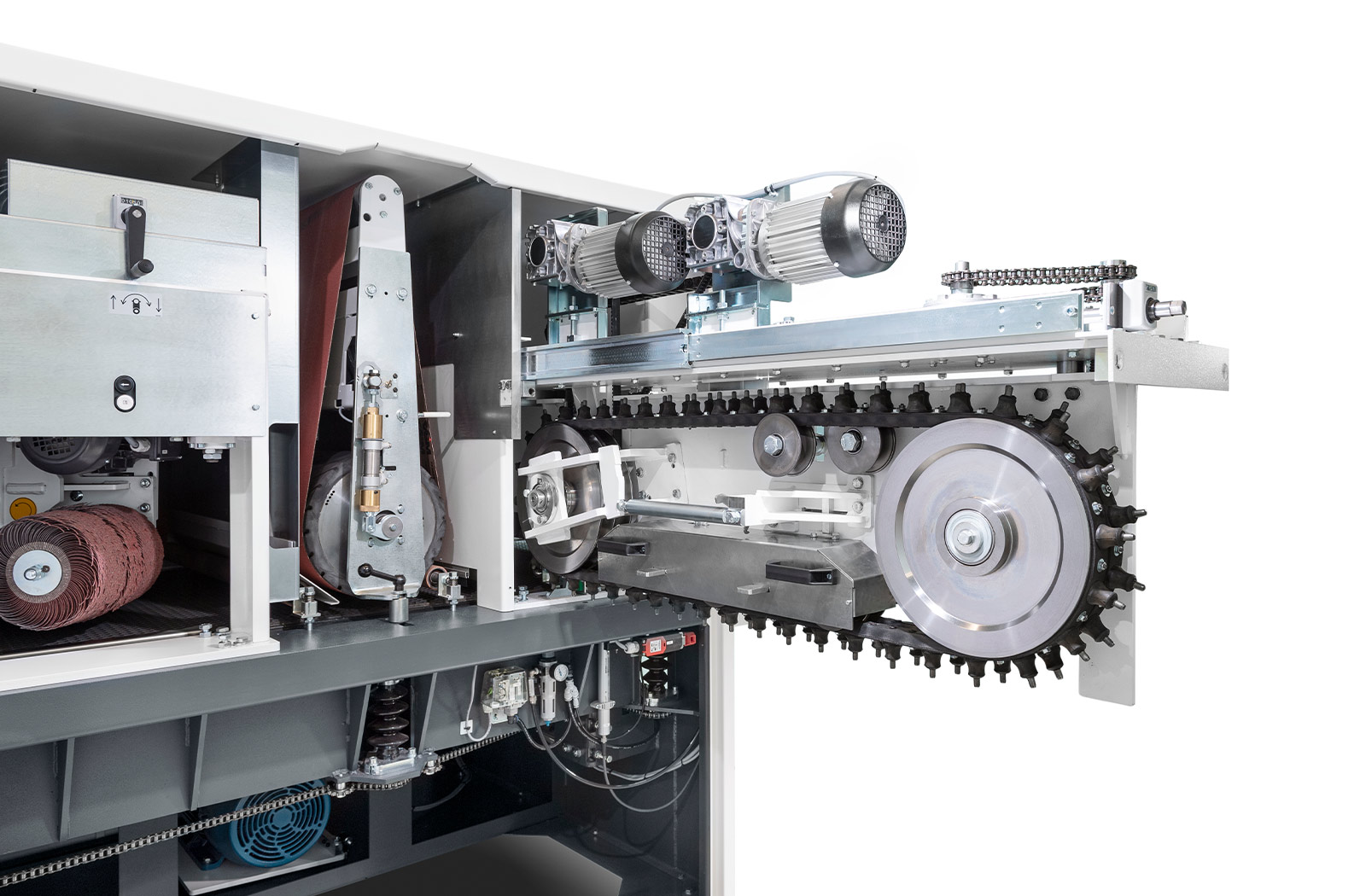

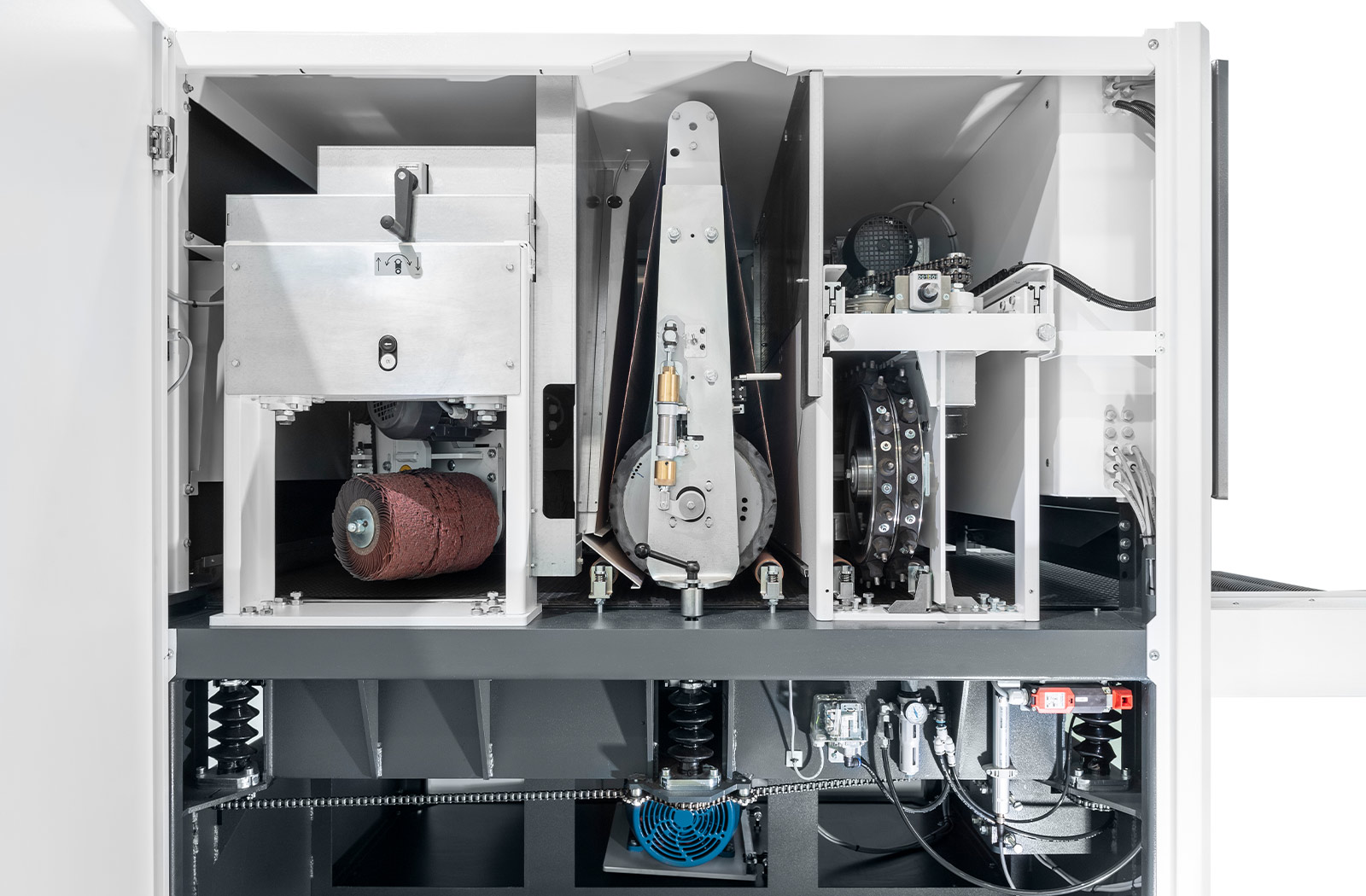

The SMD 133 DRE from LISSMAC is a universal grinding and deburring machine for removing slag and for deburring and edge rounding on oxy-fuel and plasma cutting steel and stainless steel parts. The system, which has a robust, long-life conveyor belt for heavy workpieces, is used for mechanical slag removal and edge rounding on thick metal sheets.

The slag is mechanically knocked off by the D unit with LISSMAC power pins (hard metal pins). Due to 90 percent mechanical burr removal by the power pins, any remaining burr can be removed without introducing heat into the workpiece. This so-called "cool grinding" is gentle and cost-saving for the grinding tool. The SMD 133 DRE accomplishes three work steps in one operation: slag removal, sheet deburring and edge rounding.

Operation is intuitive via a touch panel. The optimal accessibilitysimplifys tool changes, cleaning and maintenance. The quick and easy tool change optimizes the machining process. Thanks to its compact design, the system also only takes up a small amount of space in the workshop.

Technical data

Further information

- Removing slag,deburring and edge rounding in one throughfeed pass, saves time

- The high quality and solid construction of the machine guarantees a long lifetime

- The mechanical removal of slag by power-pins gives long tool life and reduces grinding costs enormously

- A soft, large diameter, contact roller, enables to process warped parts and accepts thickness tolerances

- Our 2 rotary heads give a perfectly even edge rounding

- Both mild- and stainless steels can be processed

- The compact construction of the machine requires limited floor space

- The serrated infeed pressure rollers quarantee a safe and easy feeding of parts

- The ergonomical and intuitive controls make it easy to operate the machine

- The individual operation of each head guarantees an optimum flexibility of the machine for various applications

- The optimum accessibility of the machine enables easy tool change, cleaning and maintenance

Downloads

Examples