Professional Deburring in Metalworking with Highly Efficient LISSMAC Deburring Machines

High-quality processing of workpieces for burr removal

Working with metal requires the highest precision. At LISSMAC, we help our customers achieve quality and productivity goals by automating their deburring operations. Our machines ensure efficient deburring, edge rounding up to a radius of 2 mm, removal of oxide layers, effective slag removal, and precise surface grinding. We also offer customized approaches for small part processing. Industries such as laser job shops, stainless steel processors, steel service centers, and automotive suppliers benefit from our complete, integrated systems focused on metal finishing.

SBM-XS G1E1

Double sided deburring of small parts - Deburring and uniform edge rounding on all sides of parts, both on outer- and inner contours, in a single pass

SBM-M S2

Deburring and edge rounding of steel and stainless steel on both sides in one single pass

SBM-L G1S2

Deburring machine for grinding, deburring and edge rounding of punched, laser and high definition plasma cut parts in one single pass

SBM-L G1S2 EVO

Deburring machine for grinding, deburring and edge rounding of punched, laser and high definition plasma cut parts in one single pass

SBM-XL G2S2

Deburring and edge rounding of laser, plasma and oxy fuel cut parts on both sides in one single pass

SMD 123 RE

Dry grinding machine for deburring, consistent edge rounding and surface finishing

SMD 133 DRE

Economical removal of slag, deburring and edge rounding on plasma- and oxy-fuel cut parts

SMD 3 S - EDITION

Outstanding results on the edge and on surface

SMD 3 P - EDITION

Highest-end edge rounding

SMW 5

Grinding machine in wet execution for the perfect surface finish

What is a burr?

In sheet metalworking process, a burr is a small, raised edge or rough ridge that remains on the metal after cutting, punching, or machining. It’s usually an unwanted byproduct caused by material deformation or tearing during the cutting procedure. Burrs can affect part quality, safety, paint adhesion and assembly, so so burr removal is a critical step performed using deburring machines as part of the overall metalworking operation.

Applications

Thin Sheet Metal Processing

In modern metalworking, thin-gauge sheet metal parts are often laser-cut or punched parts, leaving residual raised edges and other external imperfections. These require deburring and edge rounding prior to further production stages. LISSMAC deburring machines are designed to meet specific needs based on part geometry, quantity, material type, and technical requirements—ensuring optimal and repeatable results in every production step. Due to the thin nature of material, sheet metal is more easily deformed during punching operation. Uneven parts are harder to deburr, so may require levelling, or need upward and downward fixing during deburring, e.g. with double-sided treatment on the LISSMAC SBM series. Our machines guarantee efficient metal flash removal removal even on complex geometries, ensuring smooth edges and improved product quality.

Example of a deburring machine in use on thin sheet metal: Clearly visible are the untreated edges with burrs in their original state, as well as the clean, smoothed edges after processing.

Thick Sheet (Plate) Metal Processing

When dealing with plate or thick metal parts, especially those plasma cut parts in demanding metalworking operations, stubborn burrs and slag can form. These are often difficult and time-consuming to remove manually.

Plate metal parts are inherently heavier that thin sheet parts – worth considering when selecting a machine. One-sided machines such as the SMD and many common deburring machines require two passes, needing to turn the part. However, these solutions achieve higher degrees of edge rounding, up to radius 2 mm in a single pass. Double-sided machines remove the need to turn parts, as they process the material on top and bottom simultaneously.

Example of a deburring machine in use on thick sheet metal: Clearly visible are the untreated edges with burrs in their original state, as well as the clean, smoothed edges after processing.

The deburring process

Deburring unit

The deburring process is carried out using abrasive belts or abrasive brushes. Commonly used abrasive materials used on grinding belts include corundum, silicium carbide and ceremic. The grit size may vary from P 36 to P 180, the higher number being the smaller grit size, resulting in lower yet finer material removal. Which grinding belt and which material is used is determined by the surface quality required, the aggressiveness, removal to time ratio and the stand time of the tool, as well as the material to be grinded.

Rate of removal

On a LISSMAC machine, the rate of removal is determined by three factors: Grinding tool material/grit, feed rate and depth of cut (in feed). Balancing these factors correctly will lead to the ideal deburring result without scarring the part’s surface.

Wet vs. Dry Processing

Wet treatment is usually deployed during surface finishing. LISSMAC machines offer both wet and dry methods, yet if a specific coating finish such as non-directional finishes is not specified, dry operation is fully sufficient.

Interior and exterior contours

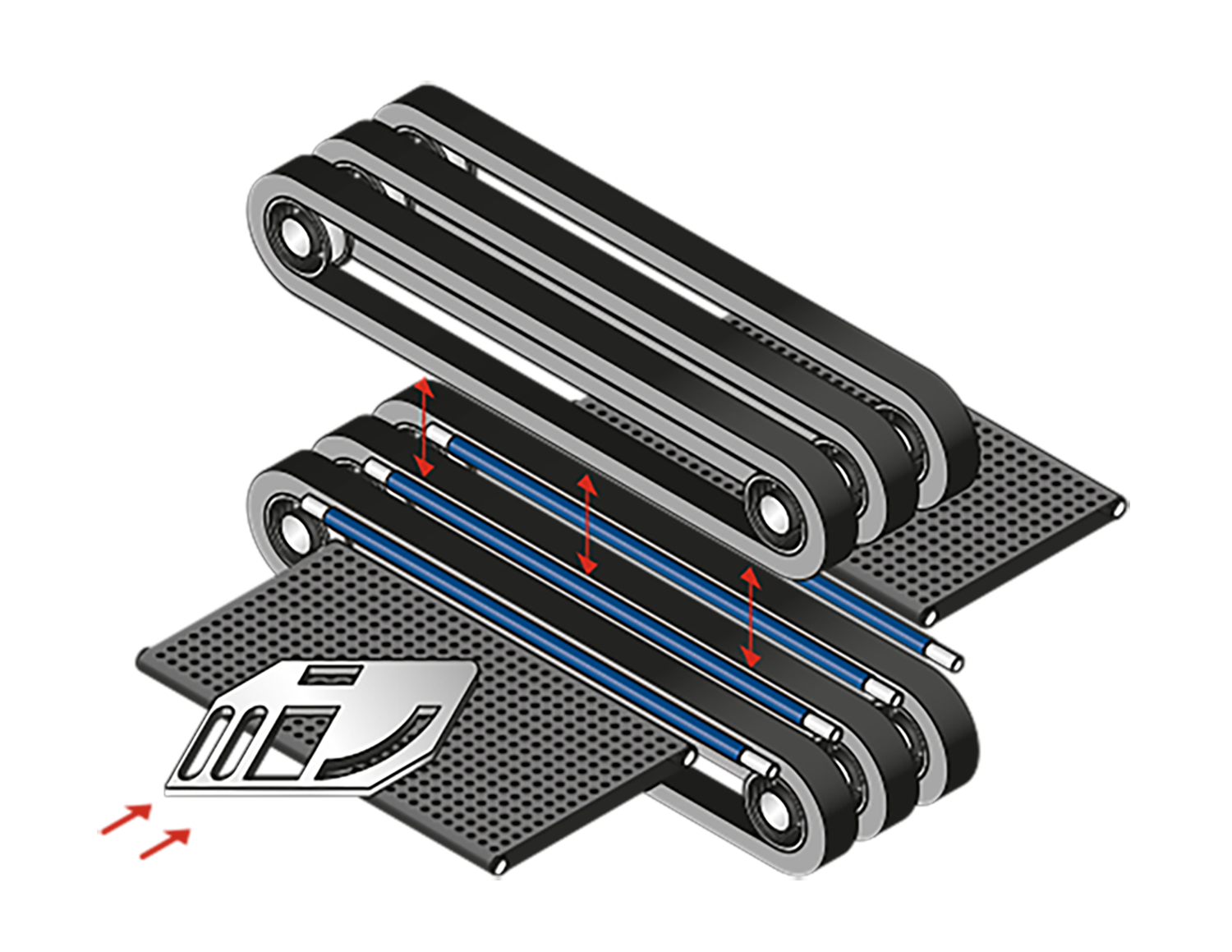

Using an innovative combination of pressure rollers on the grinding belts as well as guiding the workpiece, abrasive pressure can be applied evenly to burrs on both inner and outer contours.

Opened SBM-L deburring machine showing internal structure and processing units.

Double-sided vs. single-sided processing

LISSMAC’s unique double-sided dry machining enable simultaneous treatment of both internal and external contours in one pass. This significantly increases productivity and consistency, as no manual turning is required. Our SBM series (XS, M, L, XL) covers various working widths and unit configurations to suit different materials and production volumes. Select double-sided machines if the size of the machine footprint is critical on tight shop floors, if turning parts in several passed needs to be eliminated and if the workpiece dimensions and specifications are met be the SBM range.

One-sided machines, such as the SMD series however still have their benefits. One sided machine may achieve higher spec surfaces such as directional or non-directional finishes. They meet a higher degrees of edge rounding, up to radius 2. One sided machines tend to have lower acquisition costs than comparable, double-sided counterparts, which is later counterbalanced by higher energy costs and lower efficiency due to parts handling. Both one- and double sided solutions have their merits.

Single-sided vs. double-sided processing – Double-sided grinding increases efficiency by processing both sides at once.

Further Applications on Metal deburring machines

Edge Rounding

Sharp edges are rounded to improve handling safety and coating adhesion while reducing rust risk. Edge rounding up to 2 mm radius is possible on all sides.

Surface Grinding

High-quality surface finishes may be required on select parts, for example on aluminum and stainless steel parts. The highest level of finishing can be achieved on wet grinding machines, e.g. from the SMW series.

Slag Removal

Plasma and flame-cutting methods may produce unwanted, heavy slag. Our machines remove slag, ensuring clean parts and improved paint coating adhesion in later stages.

Oxide Layer Removal

Laser-cutting, mainly with CO2 lasers, but also with newer fiber lasers, may result in oxid layers or splashes on cut parts. However, removing oxidation from edges is crucial for subsequent treatments like painting or coating. Our brush units ensure thorough oxide removal for improved adhesion and corrosion protection.

Automated Deburring Machines and Automation Cells by LISSMAC

LISSMAC offers innovative automated deburring machines combined with fully automated robot cells for efficient sheet metal processing. Equipped with AI software and 3D vision, the cells automatically detect parts and control robot movements without programming effort. Flexible grippers ensure secure handling of diverse geometries, including compley shapes and small parts. Our turnkey solutions, including enclosures and conveyor systems, integrate seamlessly into existing production workflows. These automation cells reduce labor, boost productivity, and are ideal for small batch sizes with high variety.

Accessories for grinding machines