SBM-L G1S2 EVO

The grinding and deburring machines are suitable for machining workpieces made of stainless steel, steel, aluminum or non-ferrous metal on both sides.

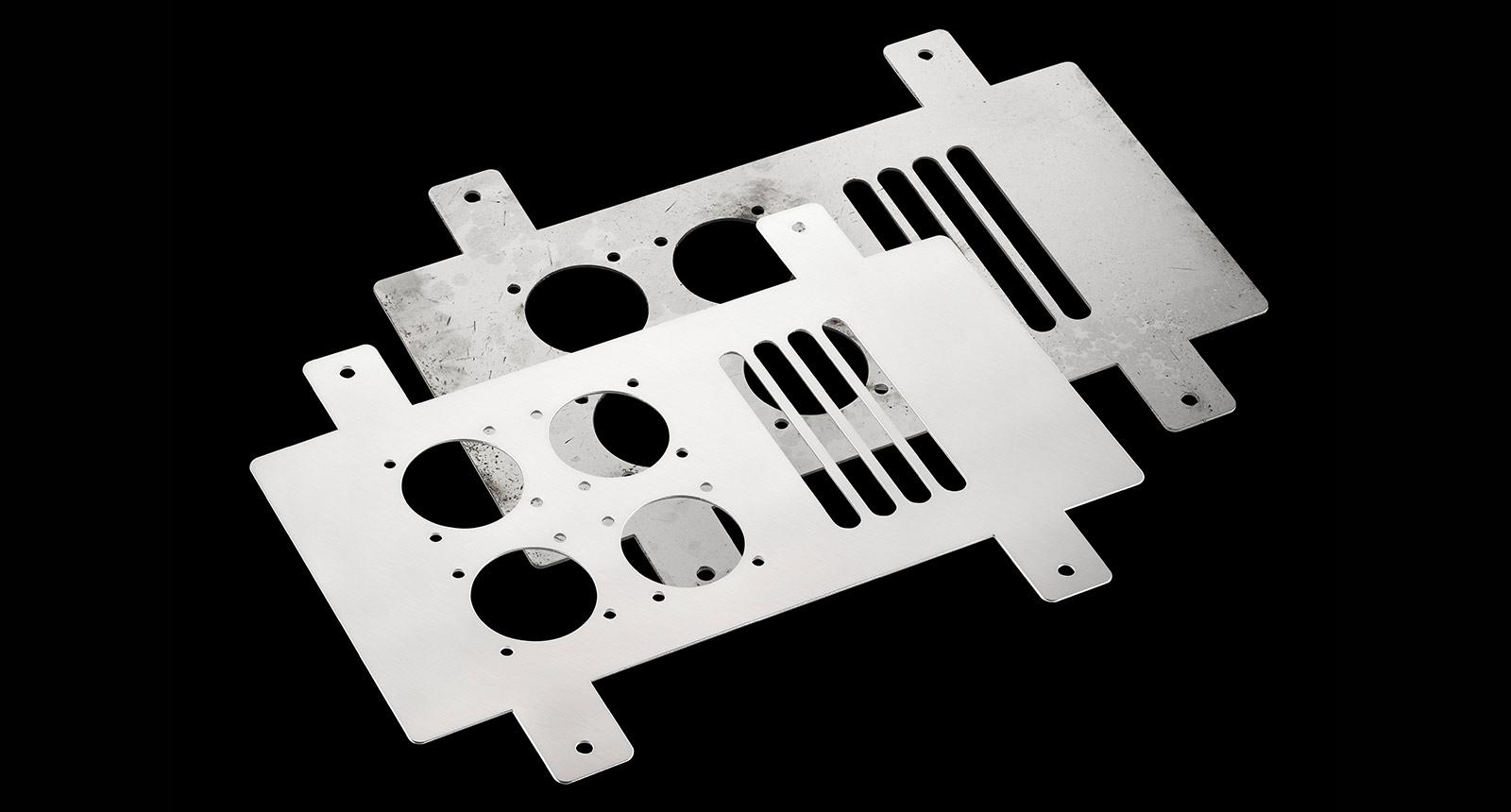

The SBM-L G1S2 EVO grinding and deburring machines were developed for deburring on both sides and edge rounding of workpieces in one operation. The LISSMAC machines are used for deburring sheet metal and processing sheet metal parts, laser parts and stamped parts. The L series is equipped with three units each on the top and bottom. The processing of stainless steel, steel, aluminum or non-ferrous metal workpieces can be done either on the upper side, the lower side or on both sides.

Two-sided sheet metal processing and edge rounding in one operation gives time savings of up to 60%. It is also possible to easily connect automation solutions or to integrate them into production lines. The machine concept ensures ergonomic operation and a pleasant working environment without pollution, dust and noise.

Technical data

3390/1480/1790mm

3890/1480/1790mm

(5512 / 6173 lbs)

3390/1480/1790mm

3890/1480/1790mm

Further information

- Double-sided deburring and edge rounding of punched, laser and plasma blanks

- More than 60% reduction in throughput time thanks to double-sided processing

- Up to 70% energy savings compared to conventional grinding/deburring machines

- LISA - The LISSMAC Set-Up Assist guides the operator automatically/without prior knowledge to the desired processing result

- 13.3" FullHD touch panel with intuitive operator guidance

- Simultaneous deburring and edge rounding on the external and exterior contours

- Double-sided processing eliminates costly material handling (e.g. turning of components) and time-consuming parts logistics

- One-sided machining possible by simply deactivating units (also for components that cannot be machined on conventional machines)

- Optimum tool utilisation across the entire working width due to transverse machining principle

- Quick and easy tool change within minutes with automatic reference run

- Maximum productivity with optimum and consistent machining quality Maximum productivity with optimum and consistent machining quality

- Small footprint due to compact design

- Modular and compact in modern machine design - smaller footprint

- Robust design and good accessibility reduce maintenance to a minimum

- Improved working environment due to reduced dust, dirt and noise levels

Downloads

Examples