SMW 1

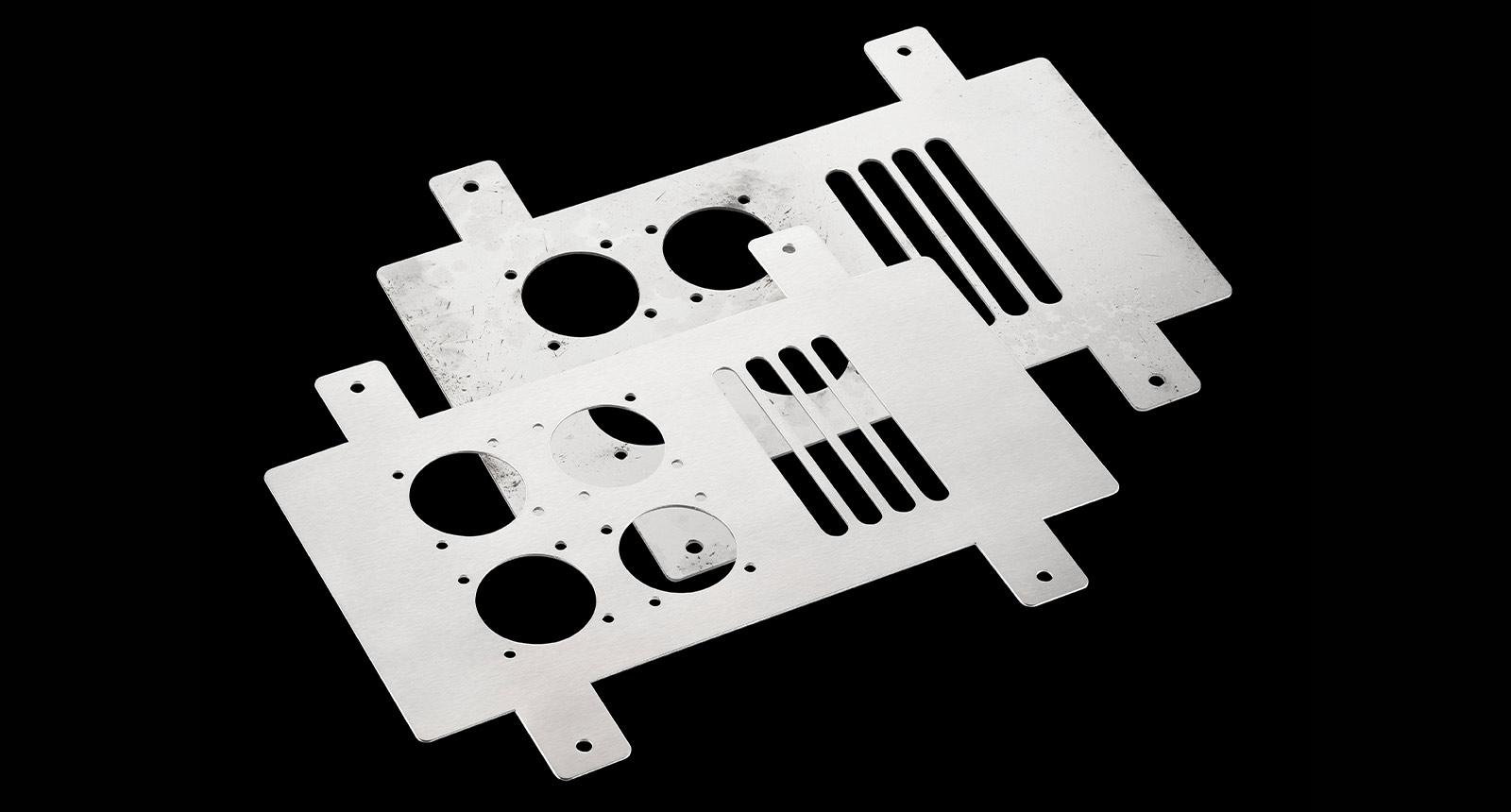

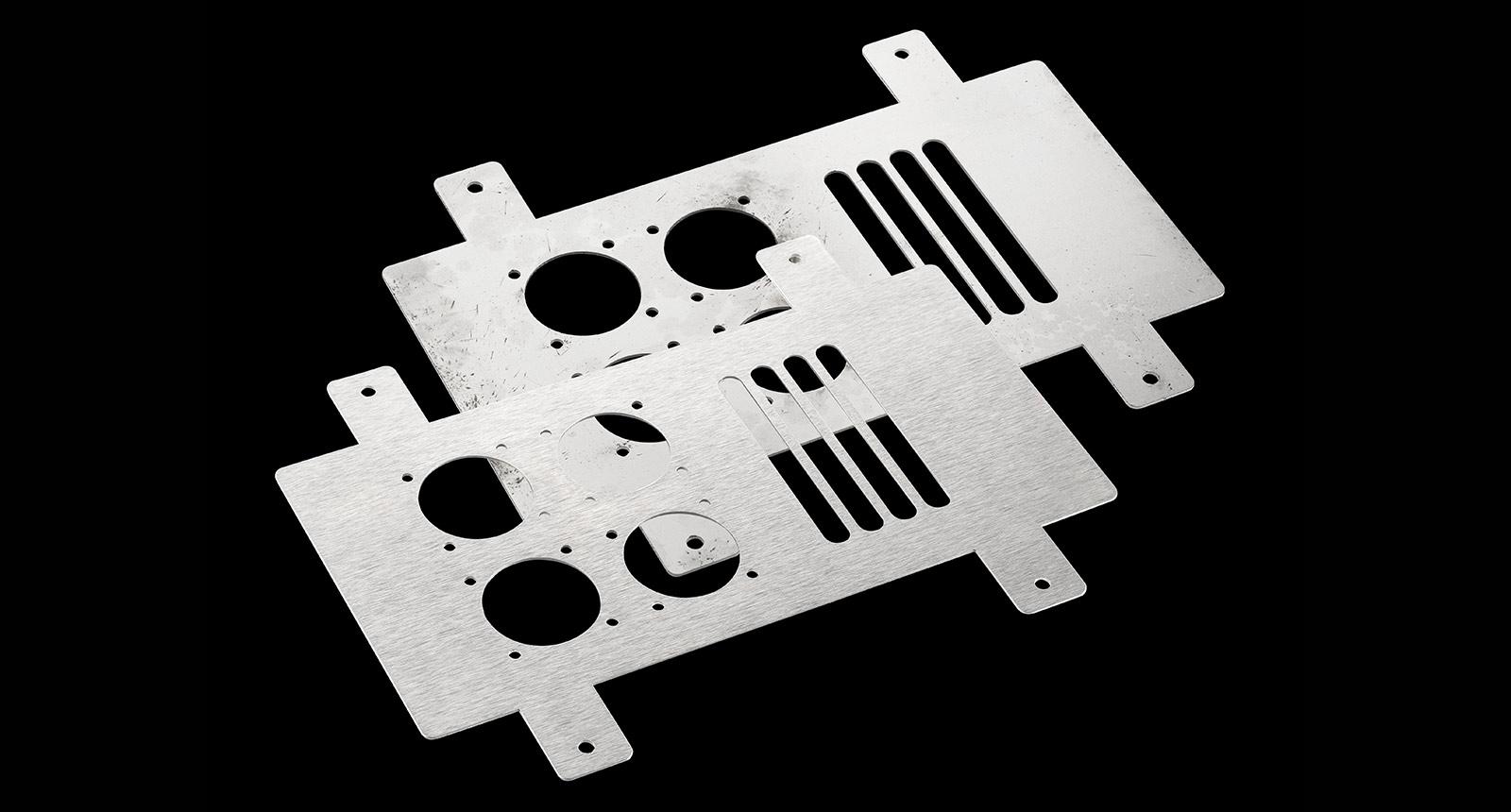

The high-end solution can be used for wet grinding any sheet metal parts, laser parts and punched parts as well as for a high-end surface finish.

Our SMW 5 series of grinding and deburring machines ensure optimum surface grinding and a unique high-end finish using the wet grinding process. The grinding and deburring machines are not only used for deburring sheet metal and rounding edges. They can also process oily components and create a decorative finish.

The high-end solution can be used to wet grind any sheet metal, lasered or stamped part. Stainless steel, steel, aluminium and non-ferrous metals can be processed.

The modular SMW 5 can be individually configured to meet customer requirements and is characterised by low tool costs, easy handling and an economical price-performance ratio.

A planetary head unit ensures strong edge rounding and uniform wear. The wet process ensures safe machining of potentially explosive materials. In addition, no heat is transferred to the workpieces. Last but not least, the SMW 5 series, which has been developed for processing thin sheet metal, offers short set-up times when mixing materials.

Technical data

Further information

- Universal and flexible use for deburring and finishing

- Our tried-and-tested wide-belt sanding unit is used in the first processing step

- The second processing unit can be fitted alternately with a disc brush or round brush cassette

- Perfectly suited for material mixes and processing critical materials such as aluminium, magnesium or titanium

- No material carry-over ensures optimum component quality and reduces set-up times and reworking

- The cooling machining process reduces the heat input into your workpieces.

- Effective machining of oily components

- Clean, corrosion-protected components after machining

- Intuitive operating with a touch panel

- The efficient, integrated cooling lubricant system guarantees a long service life of the cooling lubricant and the best machining results

- Dust-free processing provides a clean workplace for your employees and reduces health risks

- No dust extraction necessary

Examples