SFA 400

Mobile, manual, extremely efficient. The one-man sludge filter press drastically reduces disposal costs of drilling and cutting sludge. It produces benefits for the construction company and the environment.

The SFA 400 dirty water filtering system opens up enormous potential for reducing the disposal costs for sludge. The mobile one-man sludge filter press separates the solid components from the water, drastically reducing the volume to be disposed of.

The sludge cake obtained from waste from concrete slurry can be disposed of quickly and easily via building material recycling.

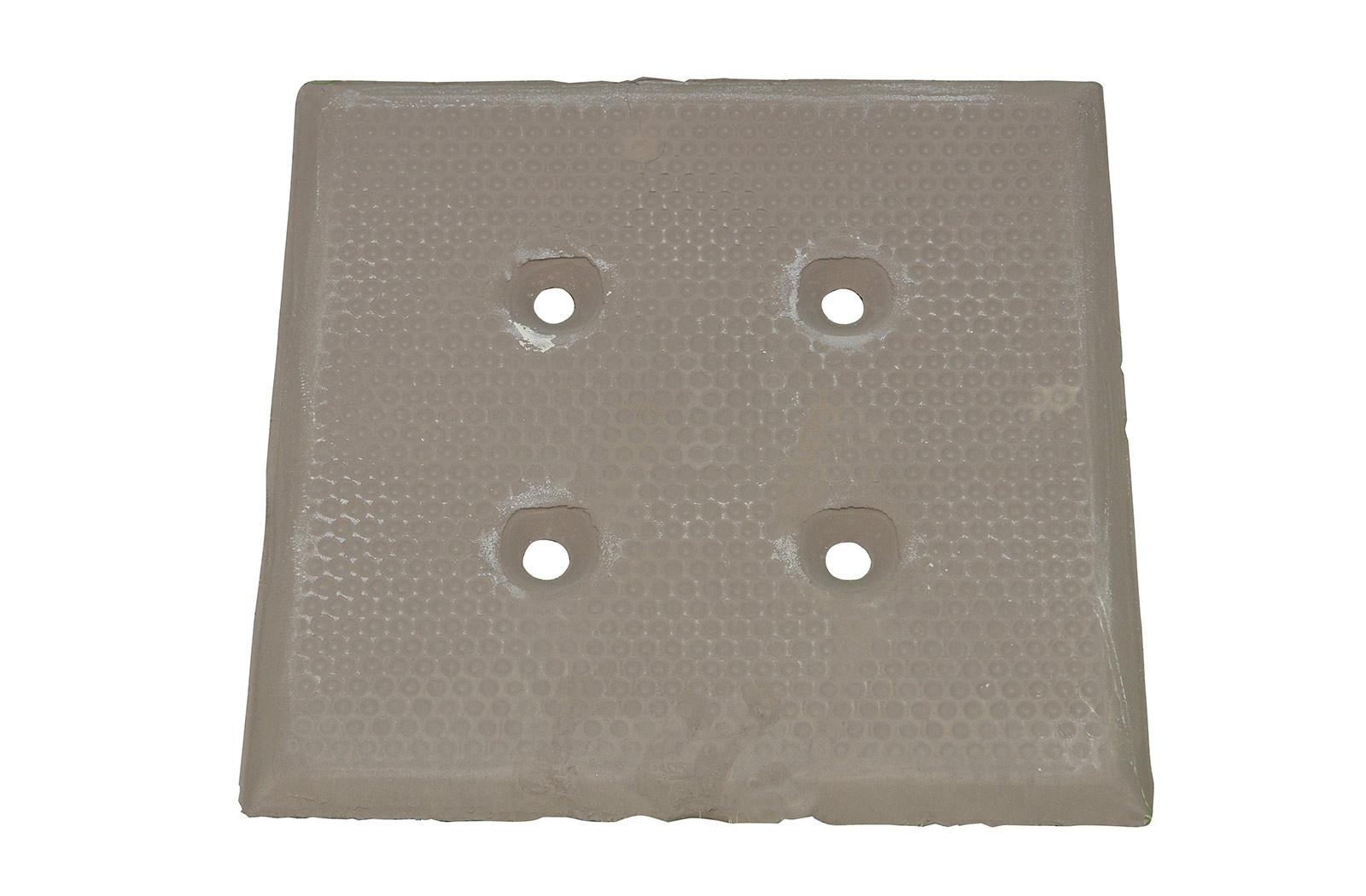

The recycling capacity of the manual chamber filter press is 480 l / h. The chamber filter press is ideal for all construction sites where drilling and cutting work is be carried out and wastewater disposal is necessary. Clean water from the chamber filter press can be returned to processing machine for tool cooling generating savings through significantly lower requirements for fresh water and lower water transport costs. On the construction site, the highly mobile sludge filter press reduces effort with its space-saving dimensions and a low weight which make transport easier. The chamber filter press is operated manually by with a hydraulic hand pump and the robust, low-wear compressed air diaphragm pump is designed for continuous use.

Both the construction company and the environment will benefit from the use of the SFA400 mobile dirty water filter system

SFA 400. Discover the advantages:

Technical data

Further information

- Essential reduce of the fresh water consumption as well as of the transportation costs for the fresh water

- The cleaned water can be fed back to the cutting equipment in order to cool the cutting tool

- Essential reduce of the disposal costs by separating the solids from the slurry or waste water and by reducing the disposable liquid volume to a solid filter cake only

- The filter cake briquettes can be easily and quickly disposed

- The chamber filter press is closed by a manual hydraulic pump

- Robust and durable pneumatic diaphragm pump for continuous use

- Simple and fast cleaning of the filter unit

SFA 400

- Mobile one-man sludge filter press

- Aluminium sack trucks (steps up to 22cm are not a problem)

- Space saving transport dimensions

- Lightweight

- The filter system can be completely disassembled

- Small-sized filter unit for long working periods without interruptions