ZBS

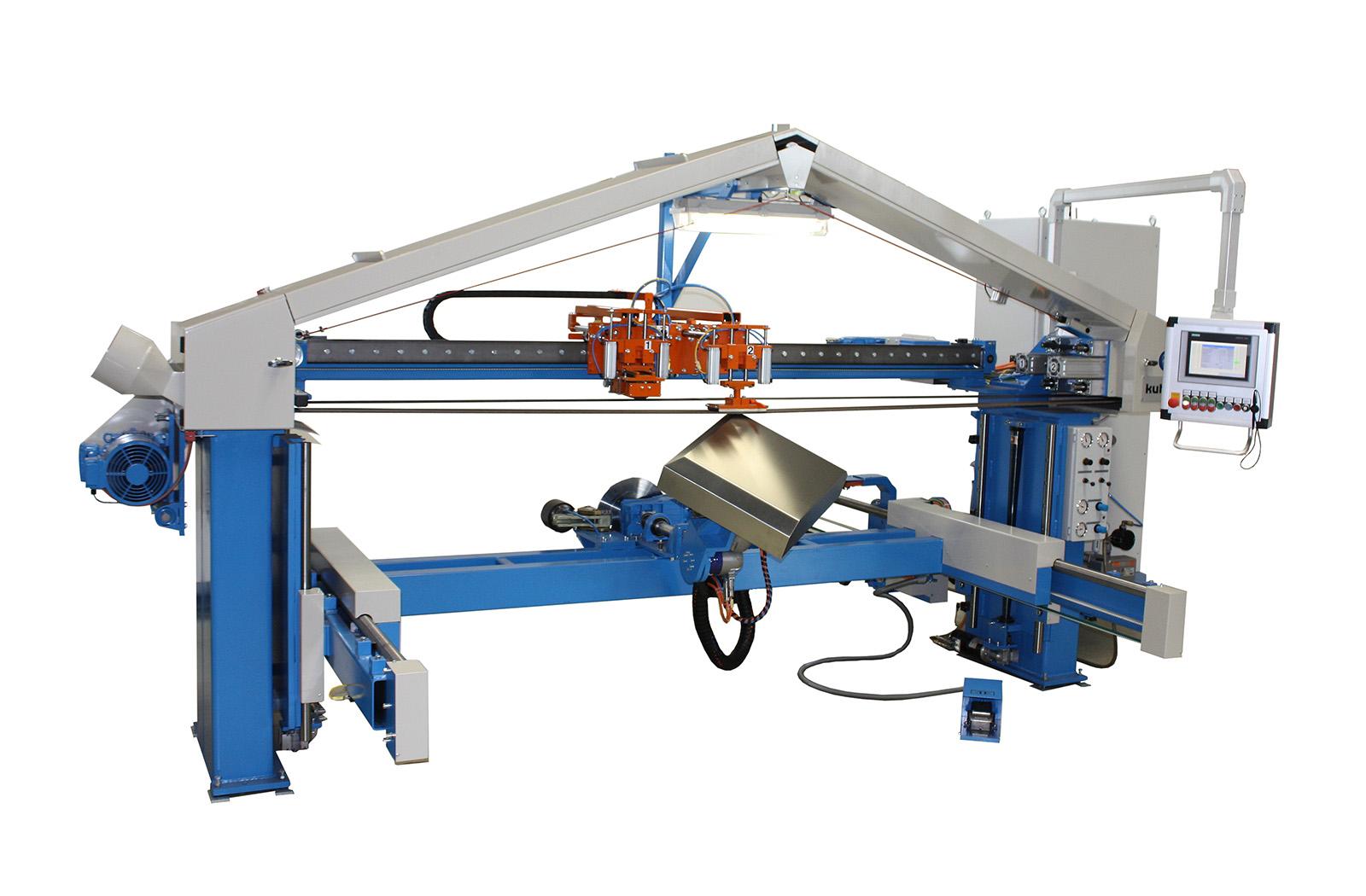

Twin-belt Grinding Machine Type ZBS

The configurable machine for ergonomic grinding of surfaces on plates, sheets or formed and welded three dimensional components.

The Twin Belt Grinding Machine ZBS is built for the roughing and finishing on welded edges, corners and surfaces on flat and mid-size workpieces out of steel, stainless steel, and aluminum, i.e. doors, frames, cabinets, housings, hoods, furniture parts, frame parts in automotive and aircraft – manufacturing, round bins, cylinders, heaters etc.

The ZBS is also available as the ZBS Robotoc - for full grinding automation.

Contact salesTechnical data

ZBS 1

Table size

2800 x 800 mm

Main motor power

4 kW (5,5 kW)

Grinding belt velocity

8-25 m/s

Table height adjustment

0 - 630 mm

Grinding belt length

7100 mm

Footprint without table rack

3600x 2000 mm

Footprint with table rack

3600 x 3500 mm

Machine height

ca. 2650 mm

Dust extraction and filter untit

Connector flange ø 200 mm / required airflow 3000 m³/h

Power connection (with dust extraction)

6 kW (12 kW)

Compressed air

6 bar

ZBS 2

Table size

3000 x 1000 mm

Main motor power

4 kW (5,5 kW)

Grinding belt velocity

8-25 m/s

Table height adjustment

0 - 630 mm

Grinding belt length

9000 mm

Footprint without table rack

4750 x 2300 mm

Footprint with table rack

4750 x 3800 mm

Machine height

ca. 2500 mm

Dust extraction and filter unit

Connector flange ø 200 mm / required airflow3000 m³/h

Power connection (with dust extraction)

6 kW (12 kW)

Compressed air

6 bar

ZBS 3

Table size

4000 x 1000 mm

Main motor power

4 kW (5,5 kW)

Grinding belt velocity

8-25 m/s

Table height adjustment

0 - 630 mm

Grinding belt length

11200 mm

Footprint without table rack

5750 x 2300 mm

Footrpint with table rack

5750 x 3800 mm

Machine height

ca. 2650 mm

Dust extraction and filter unit

Connector flange ø 200 mm / required airflow 3000 m³/h

Power connection (with dust extraction)

6 kW (12 kW)

Compressed air

6 bar

ZBS 4

Table size

5000 x 1000 mm

Main motor power

4 kW (5,5 kW)

Grinding belt velocity

8-25 m/s

Table height adjustmentg

0 - 630 mm

Grinding belt length

13200 mm

Footprint without table rack

6750 x 2300 mm

Footprint with table rack

6750 x 3800 mm

Machine height

ca. 2850 mm

Dust extraction and filter unit

Connection flange ø 200 mm / required air flow 3000 m³/h

Power connection (with dust exptraction)

6 kW (12 kW)

Compressed air

6 bar

Further information

- Two grinding belts for roughing and finishing

- Triangular configuration for excellent access to and visibiloity of the working area

- Pneumatic belt tensioning with ball guide

- Adjustable grinding belt speed

- Swivel grinding belt up to 90° with perfect belt centering

- Self-centering of grinding belt

- Pneumatic actuators on belt covers

- Smooth moving high capacity prism rollers for table and contact pressre piece movement as we as table height adjustment

- Integrated safety features:

- Sliding grinding belt cover

- Safety ripcord

- Belt tension sensor

- Safety switches on doors and covers - Free swivelling pressure shoe

- Pressure roller as an option

ZBS ROBOTEC: WHY CHOOSE ROBOTEC?

- Fully automatic processing of formed and welded sheet-metal workpieces

- Workpiece handling with five programmable axes

- High availability and rapid machine set-up thanks to user friendly operating panel (Siemens S7-400)

- 30% reduced machining time due to automation

- PLC controls total of 10 axes

Examples