MBS 510

Precision and speed in aerated concrete and masonry. The stone saw offers the greatest possible reduction in effort and inspires with the longest service life.

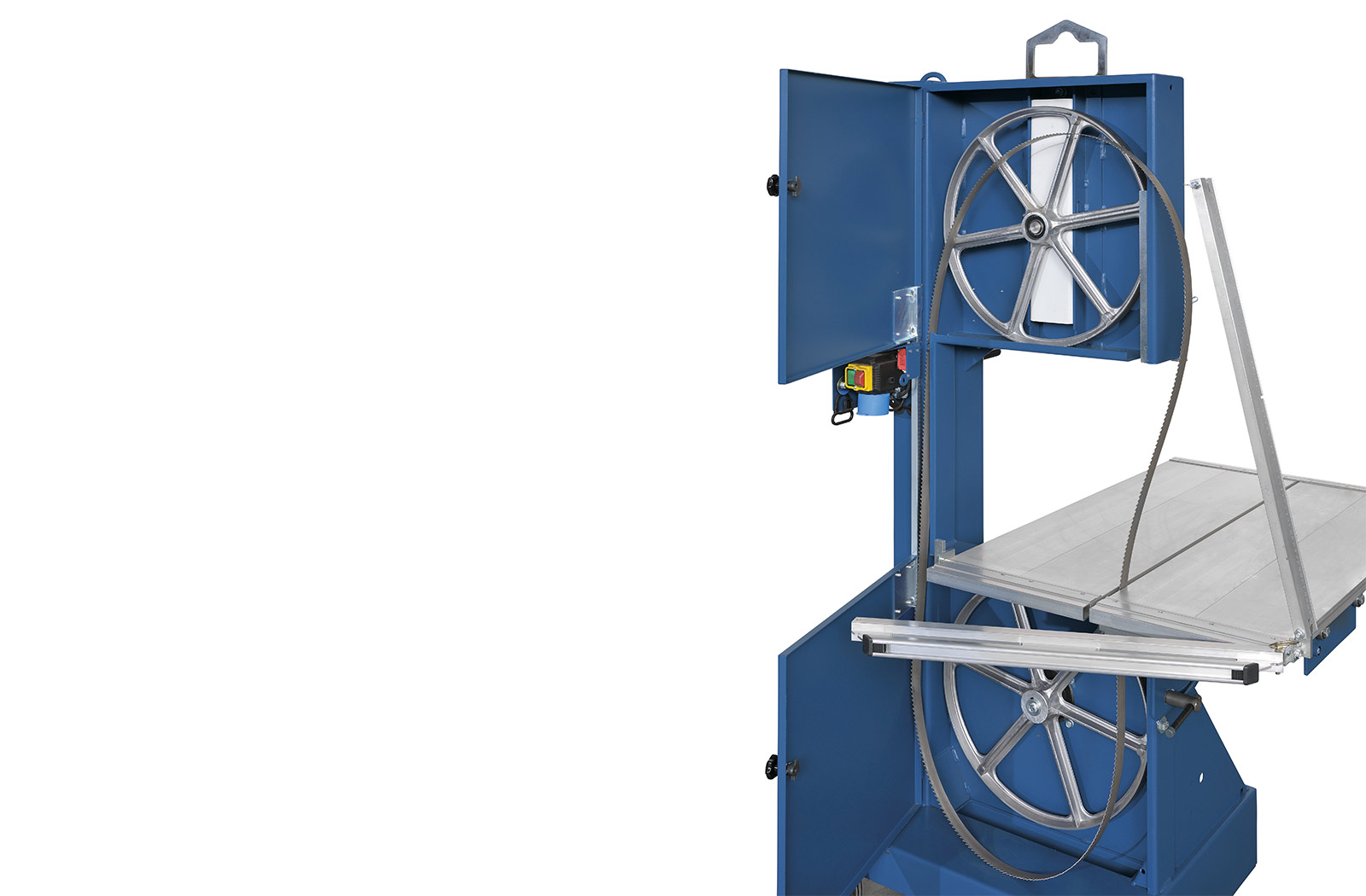

The masonry bandsaw MBS 510 is specially designed for processing aerated concrete and various bricks. The stone saw has a cutting height of up to 510 mm and a cutting length of up to 700 mm. The MBS series stands for high-precision stone cutting technology and offers the greatest possible effort saving when sawing aerated concrete and masonry.

The stone saw is at home on every building construction site and delivers outstanding performance, sawing aerated concrete and Poroton brick. Thanks to the wheelset, the band saw is easy to use and can be moved by one person. The dry saw has optimally dimensioned saw band rollers, which guarantee a long service life of the saw band. Even the robustly dimensioned direct drive of the saw band wheels reduces maintenance and operating costs.

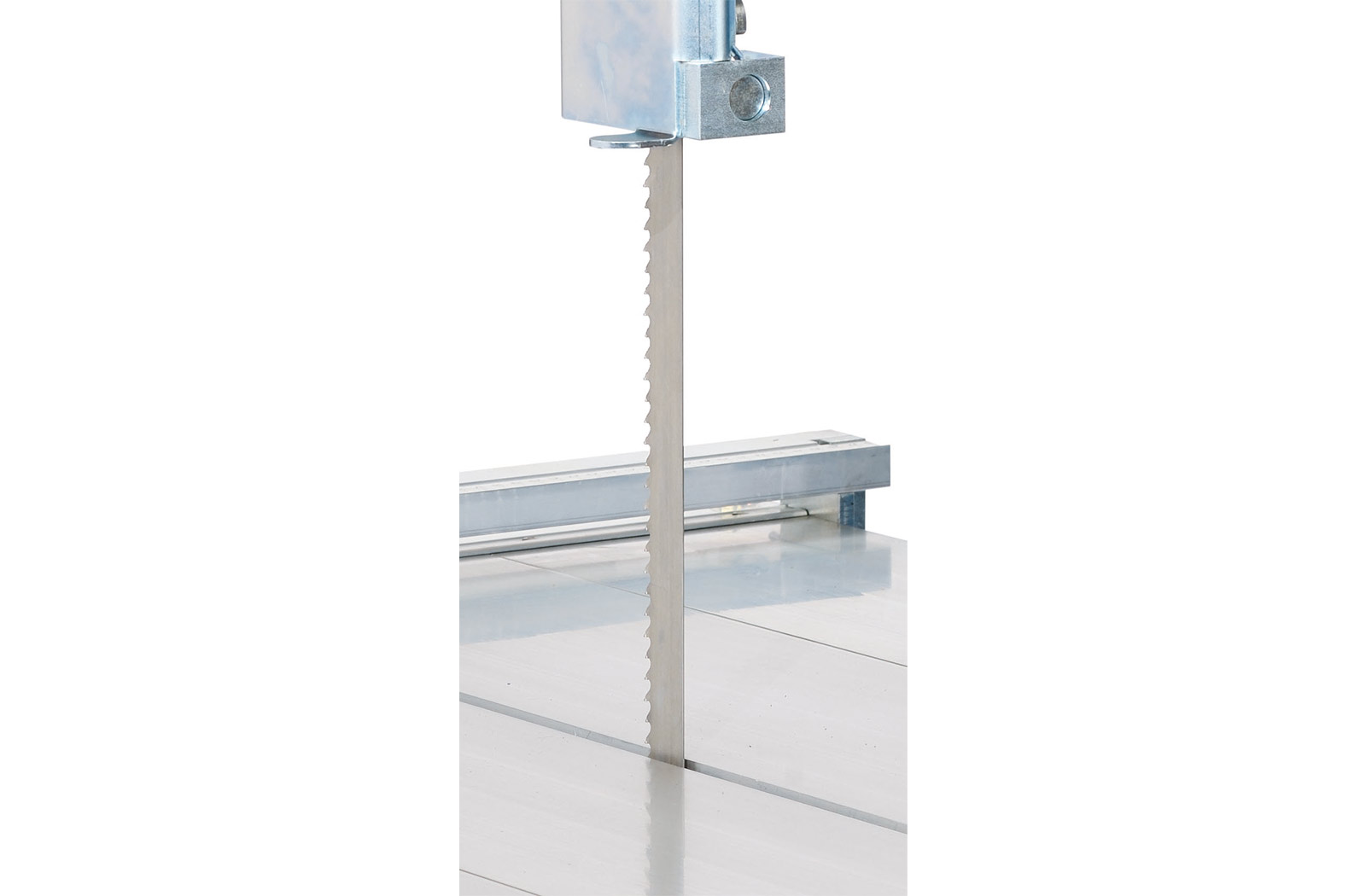

The great experience of LISSMAC is reflected in numerous practical details that result in fast operation and accurate work. The machine features constant and optimal saw band tension and automatic set clamping force for the best possible cutting accuracy while reducing the risk of saw band breakage. The quick release catch which enables the saw table to be easily opened gives short saw band changing times.

The masonry band saw MBS 510 is ideal for precise, quick and flexible sawing operations, cutting heights of up to 510 mm. See the advantages for yourself:

Technical data

Further information

- Perfect for porous concrete and bricks

- Perfectly sized saw band rollers guarantee long life of the saw band

- Direct drive saw band wheels reduce maintenance work

- A generous opening in the lower saw roller box enables the debris to pass easily

- Automatic saw band tensioner ensures optimum and constant tensioning for best cutting accuracy and reduced risk of saw band breakage

- Short saw band changing times – with quick-coupling, the saw table can be opened with one hand movement

- Automatic saw cut stop – no unnecessary saw band stress, as the saw belt only runs when actually sawing

- The wheel set allows the band saw to be moved easily by one person