Kanten afronding

Betere adhesie van de coating en minder risico ol letsel

Het gelijkmatig afronden van randen, ook wel bekend als silken, is onderdeel van het afbraamproces. Scherpe randen worden weggewerkt en rond gemaakt zodat deze veilig gehanteerd kunnen worden. Optimaal afronden verbetert de adhesie van coating aan het werkstuk en voorkomt roestvorming. Daarnaast vormen afgeronde randen een veel kleiner risico op letsel. Met slijpmachines die ontworpen zijn om op elke LISSMAC-applicaties te gebruiken, kunnen volledig afgeronde randen met een radius tot 2 mm worden verwezenlijkt.

SBM-XS G1E1

Dubbelzijdige bewerking van kleine onderdelen - ontbramen en gelijkmatig afronden van alle werkstukkanten op buiten- en binnencontouren in één bewerking

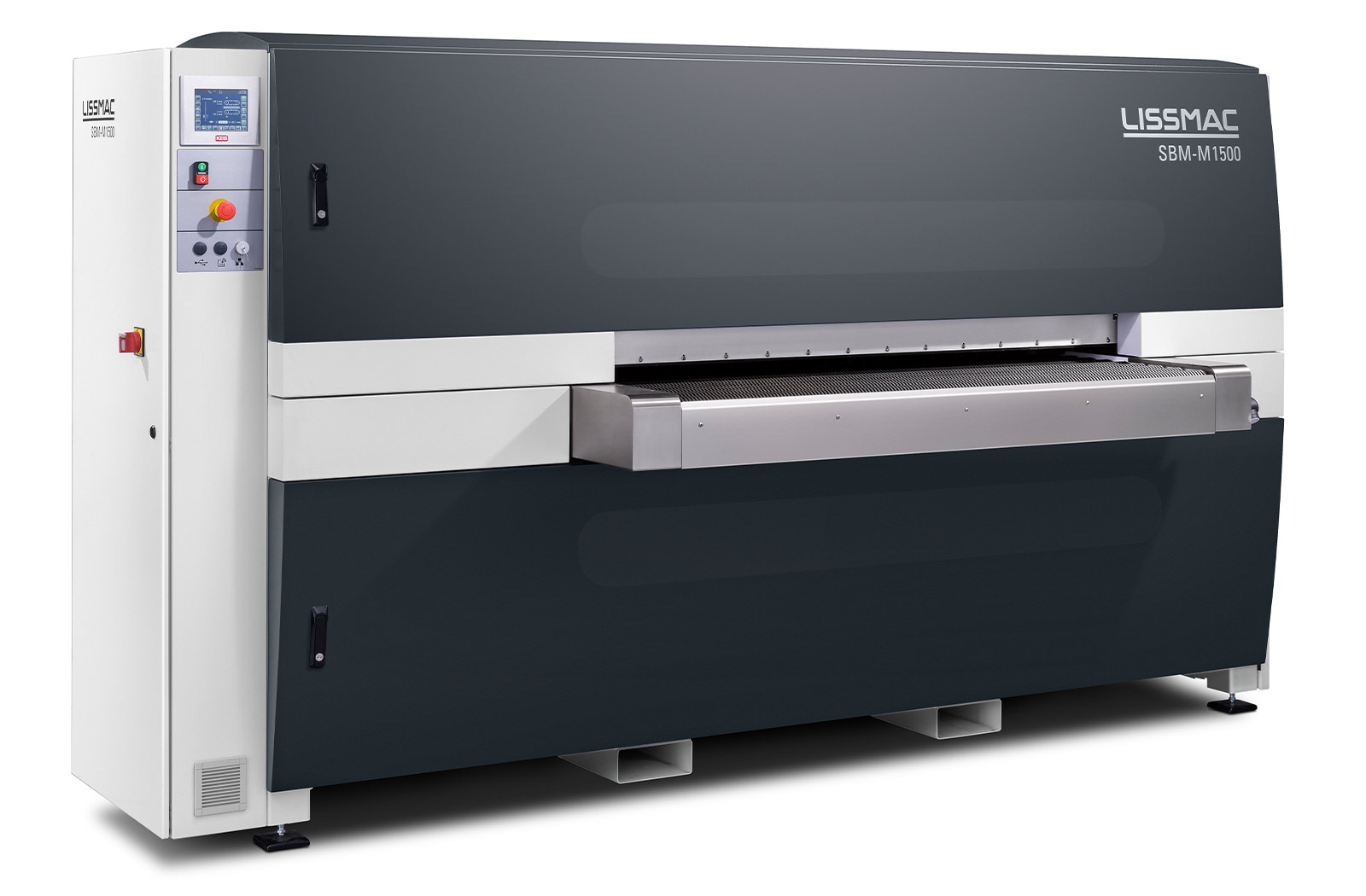

SBM-M S2

Ontbramen en kanten afronden van staal, roestvrij staal en aluminium aan beide zijden in één bewerking

SBM-M D2

Verwijdering van slak aan beide zijden van plasma- en autogeen gesneden werkstukken in één bewerking

SBM-L G1S2

Ontbraammachine voor het ontbramen en afronden aan beide zijden van gestanste, laser- en fijne plasmaplaten in één bewerking

SBM-L G1S2 EVO

Ontbraammachine voor het ontbramen en afronden aan beide zijden van gestanste, laser- en fijne plasmaplaten in één bewerking

SBM-XL G2S2

Ontbramen en kantafronden aan beide zijden van laser-, plasma- en autogeen gesneden werkstukken in één bewerking

SMD 123 RE

Droog werkende machine voor ontbramen, kanten afronden en oppervlakte slijpen

SMD 133 DRE

Economisch verwijderen van snijslakken, ontbramen en afronden van kanten van plasma- en vlamgesneden werkstukken.

SMD 3 S - EDITIE

Indrukwekkende resultaten op de kanten en op het oppervlak

SMD 3 P - EDITIE

Randafronding op het hoogste niveau

SMW 5

Natte slijpmachine voor de perfecte oppervlakteafwerking

Why Edge Rounding Matters in Modern Industries

In modern metalworking industries, precision, safety, and surface quality are paramount.

Cutting, punching, or laser processing of sheet metal inevitably creates sharp edges and burrs. These not only pose a significant risk of injury but also impair the adhesion of paints and powder coatings.

This is where edge rounding becomes essential.

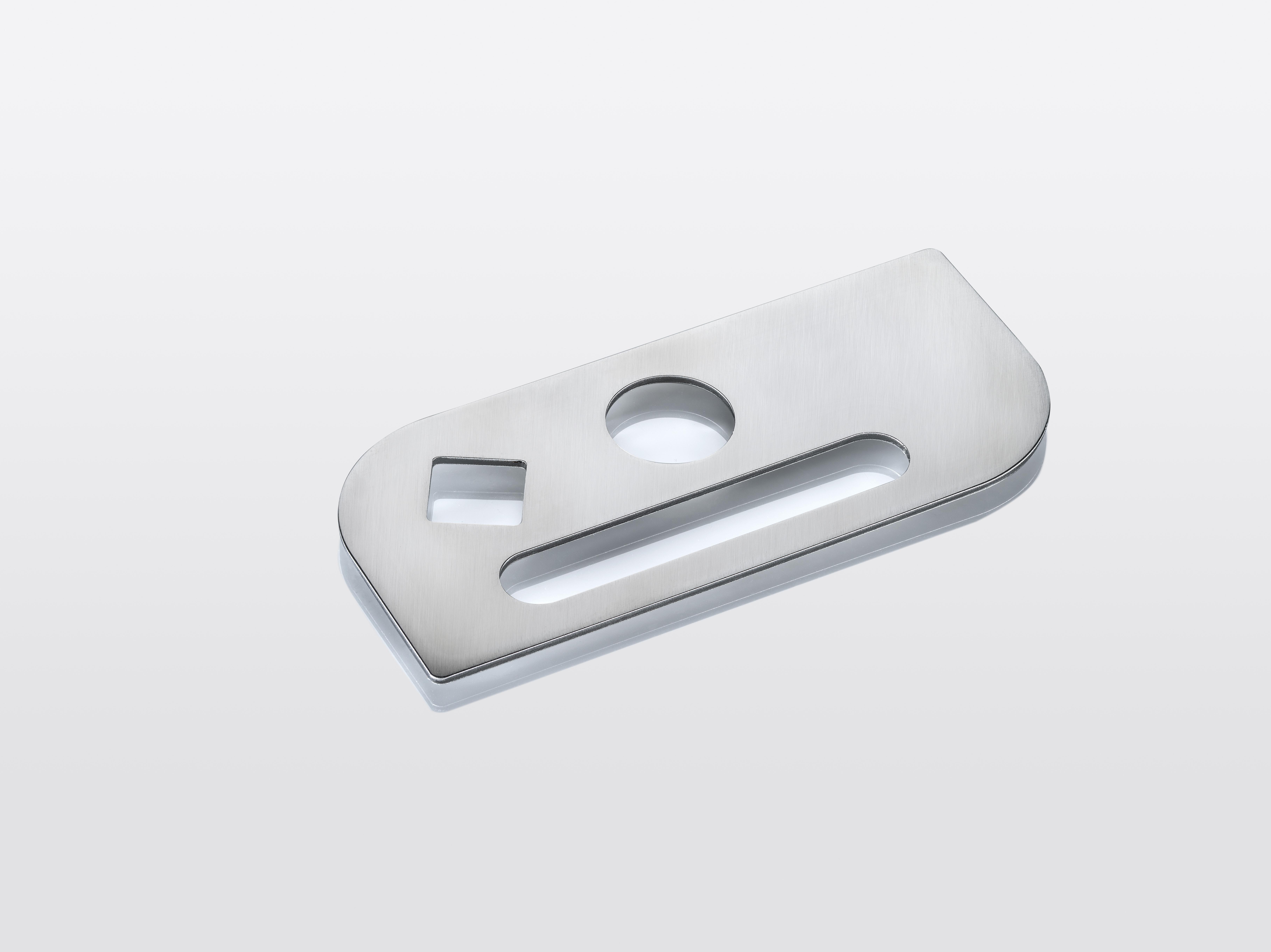

Edge rounding, also known as edge breaking, is the controlled process of removing burrs and creating consistent, defined rounded edges on all inner and outer contours of a workpiece. This improves coating adhesion and contributes to a higher overall product quality. By ensuring uniform edge geometry, edge rounding is essential for meeting increasing customer expectations regarding surface finish and durability, while also preparing components for optimal downstream processing.

The Edge Rounding Process

1. Workpiece Transport – Foundation for Precision

To achieve consistent and high-quality edge rounding, the metal parts must first be securely guided through the machines. Depending on the size, material, and shape of the metal parts, edge rounding machines are equipped with different transport systems:

PowerGrip Conveyor Belt – ideal for small or embossed metal parts, highly energy-efficient and versatile

Vacuum Table – perfect for large, sensitive metal sheets that require gentle handling

Magnetic Track – provides strong holding force for ferromagnetic steel components

These transport systems ensure stable positioning of metal parts and support accurate processing across a wide range of machines used in the edge rounding workflow.

2. Preprocessing

Before edge rounding takes place, burrs are removed using long or wide belt grinding belts. Slag and oxide layers are thoroughly removed by PowerPins and brush belts.

This step also helps eliminate secondary burrs that can compromise surface quality and downstream performance.

3. Edge Rounding - edge radius of 2 mm

In the next step, the actual edge rounding is carried out – up to a radius of 2 mm. Depending on the requirements, either sanding belts or round flap brushes are used: sanding belts provide powerful, even rounding on larger surfaces, while round flap brushes allow for precise, contour-adapted processing of even complex geometries. This precise edge rounding creates safe, smooth surfaces that excel in both surface quality and durability. The result: increased handling safety, a pleasant tactile feel, and perfect surfaces for subsequent coatings.

Additionally, the edge rounding reliably meets specific customer requirements for defined rounding radii.

Sharp Edges: Typical Applications

Edge finishing is widely used, especially where precision and finish quality are essential. Common applications include:

- Laser-cut sheets made of stainless steel, steel, or aluminum

- Punched and plasma-cut parts

- Boreholes, inner and outer contours

- Foiled parts

Sheet metal with edge rounding on both sides, processed on a LISSMAC SBM-M S2. The machine removes burrs and ensures uniform rounding of both internal and external contours.

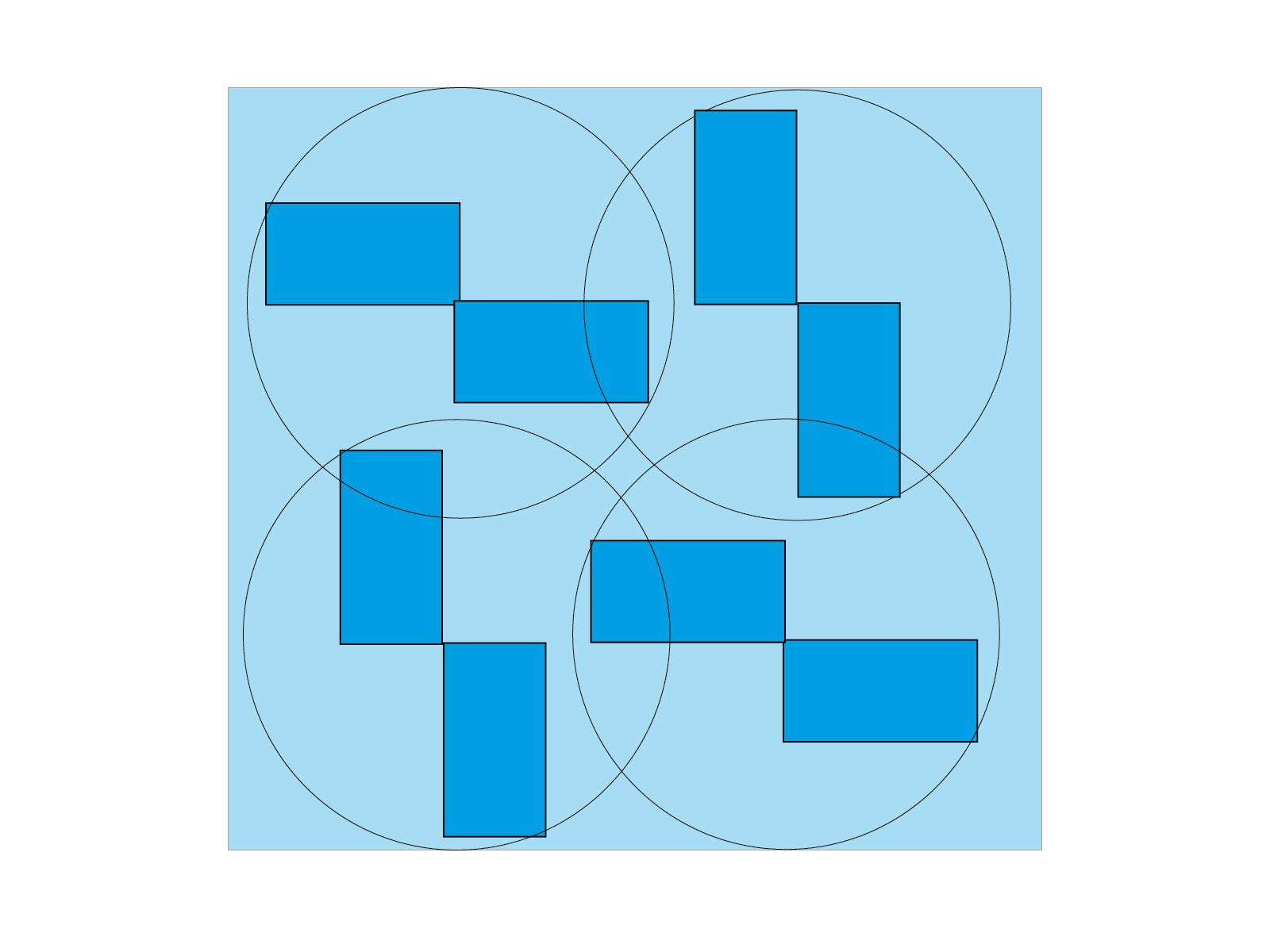

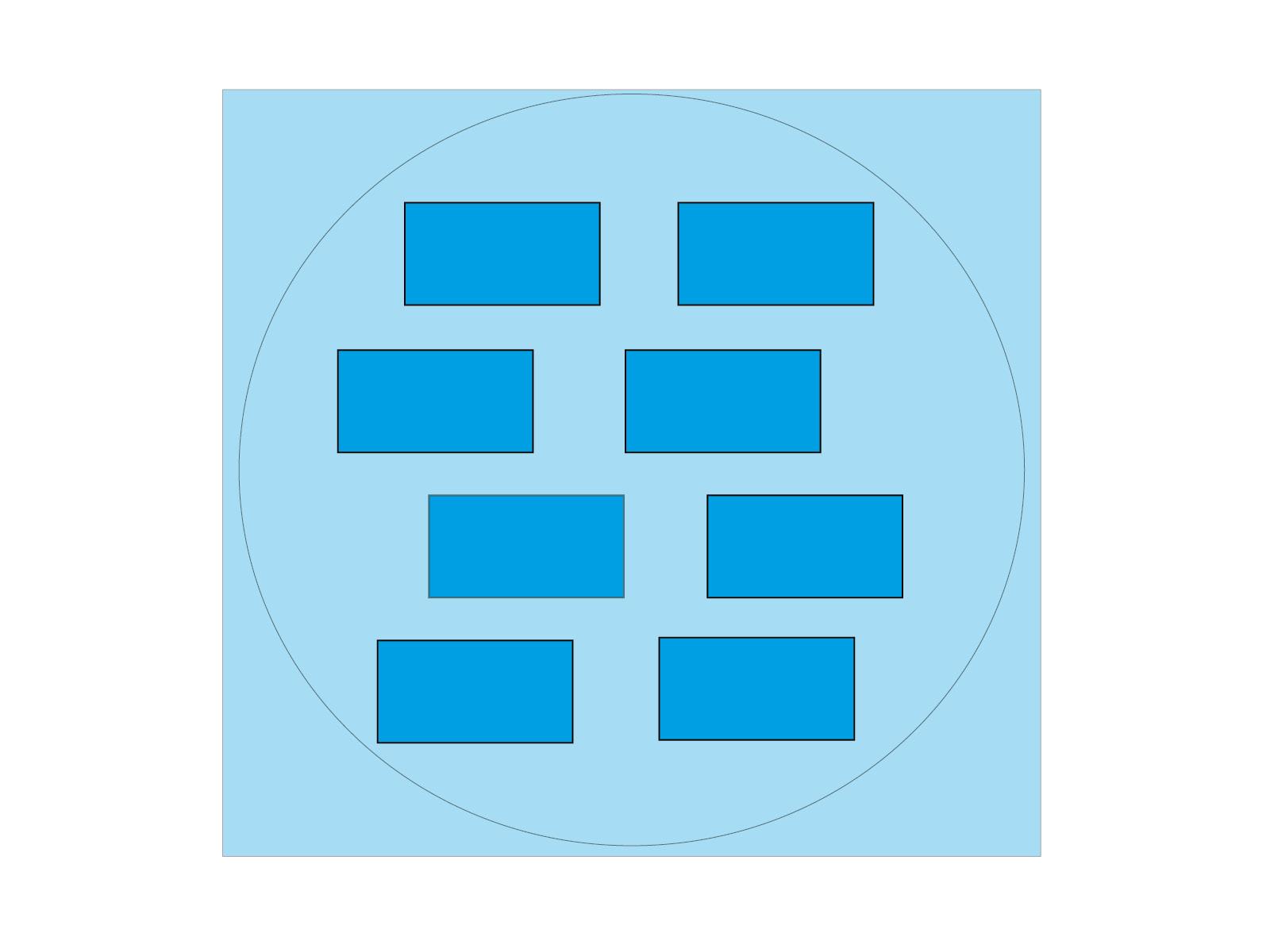

How Optimal Edge Rounding Creates Perfectly Rounded Edges – Why LISSMAC Makes the Difference

The SMD 3 series from LISSMAC impresses with its innovative, overlapping rotation system. This machine concept, featuring four rotating brush heads, enables uniform edge rounding of metal and sheet metal parts on all inner and outer contours—regardless of the part’s geometry, material, or shape. The result is a consistent edge radius across the entire working width, from 300 to 2000 mm. In combination with efficient grinding and deburring steps, users benefit from high process reliability, flexibility for a wide variety of components, and significantly improved energy efficiency.

With this, LISSMAC sets new standards in modern edge processing, ensuring consistently excellent results in both functionality and surface quality.

On the left side of the image, you can see the LISSMAC rotation system – equipped with four overlapping, rotating brush heads that ensure consistent, high-quality results. The system shown on the right, on the other hand, works with several brushes that rotate around a central axis. This can result in less rounding at the edges of the conveyor belt, while stronger rounding occurs under the central axis.