SMD 3 P - EDITION

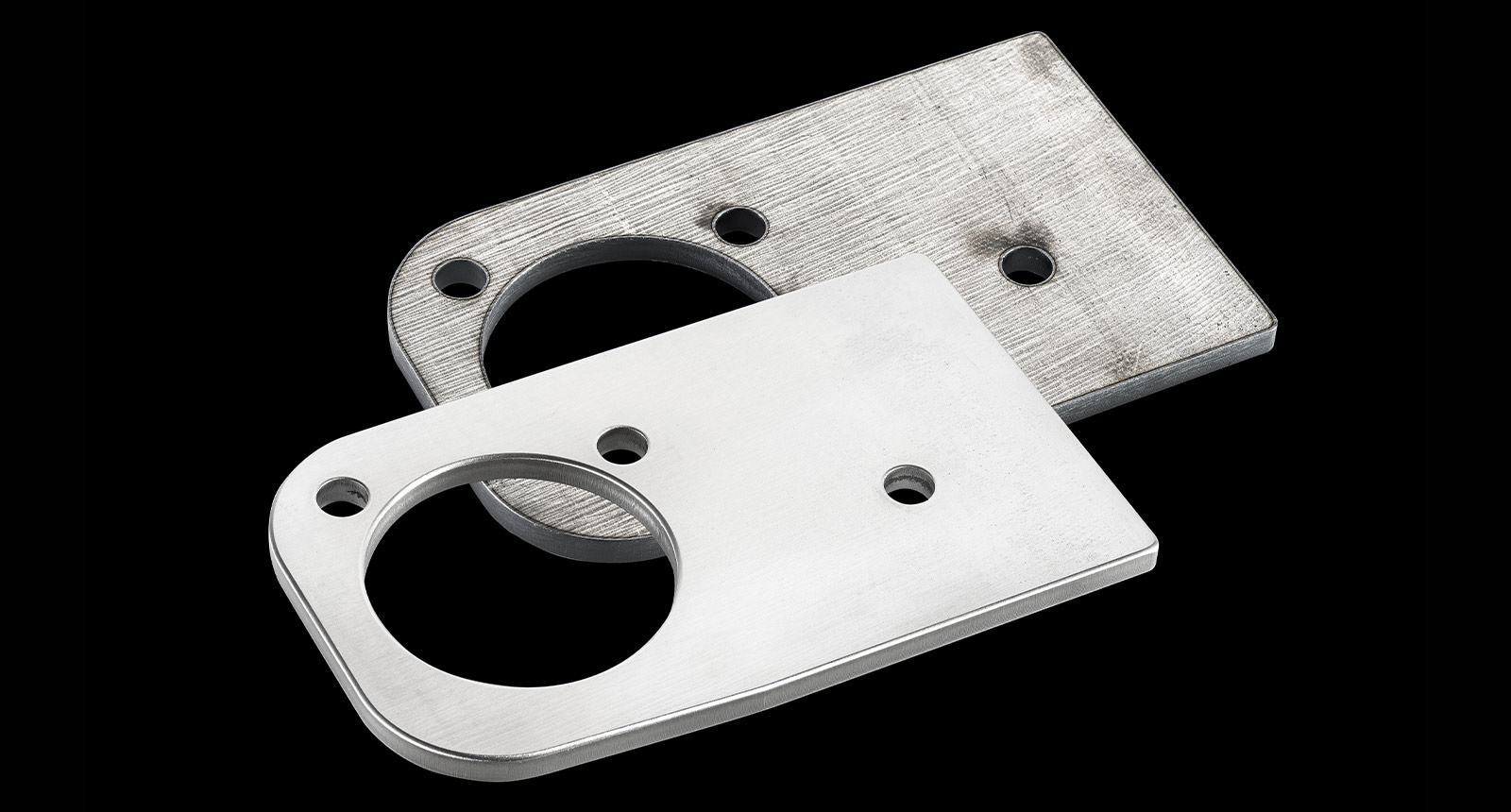

The universal grinding and deburring machine for thick sheet metal impresses with quality results in slag removal and edge rounding.

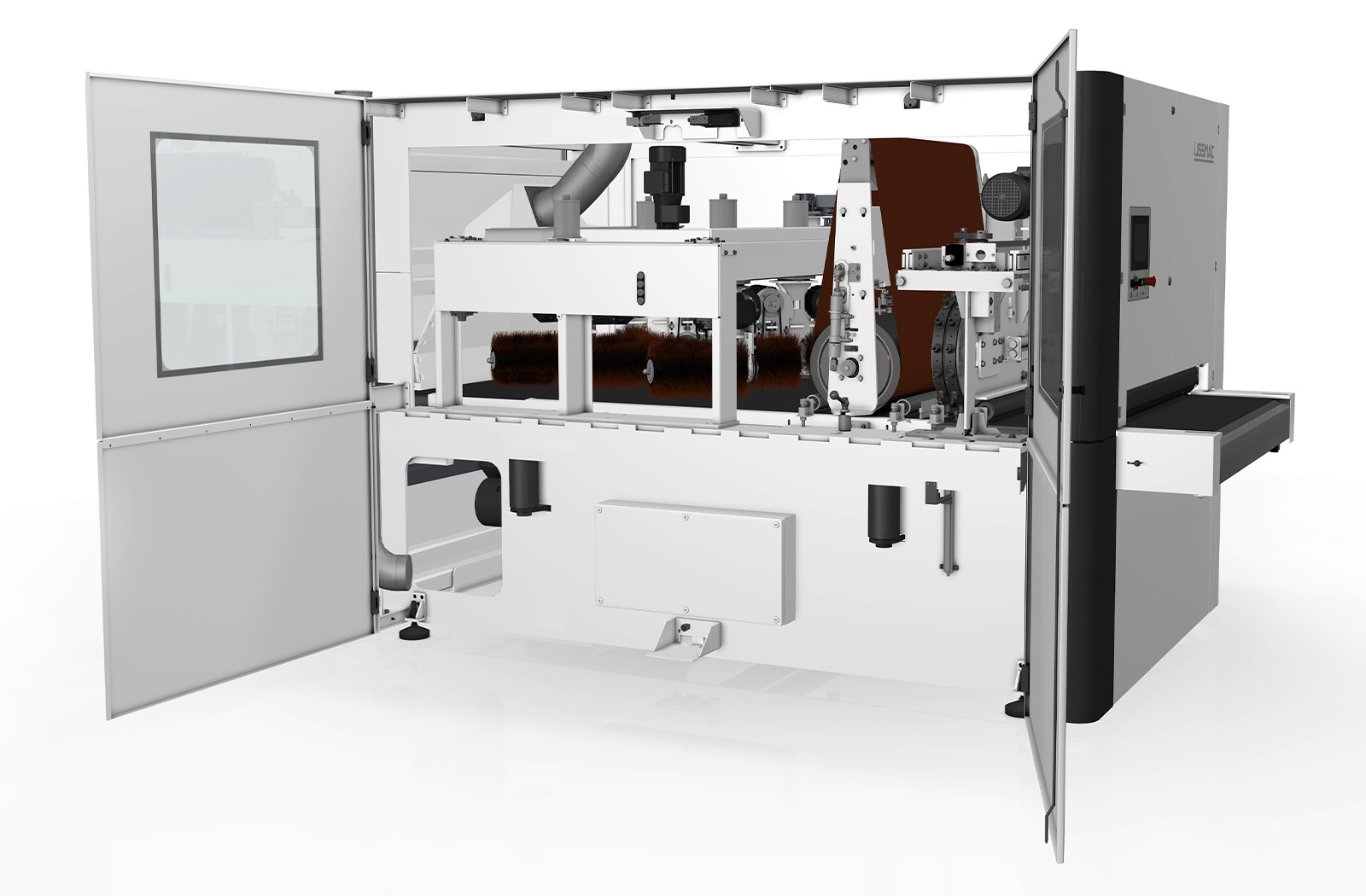

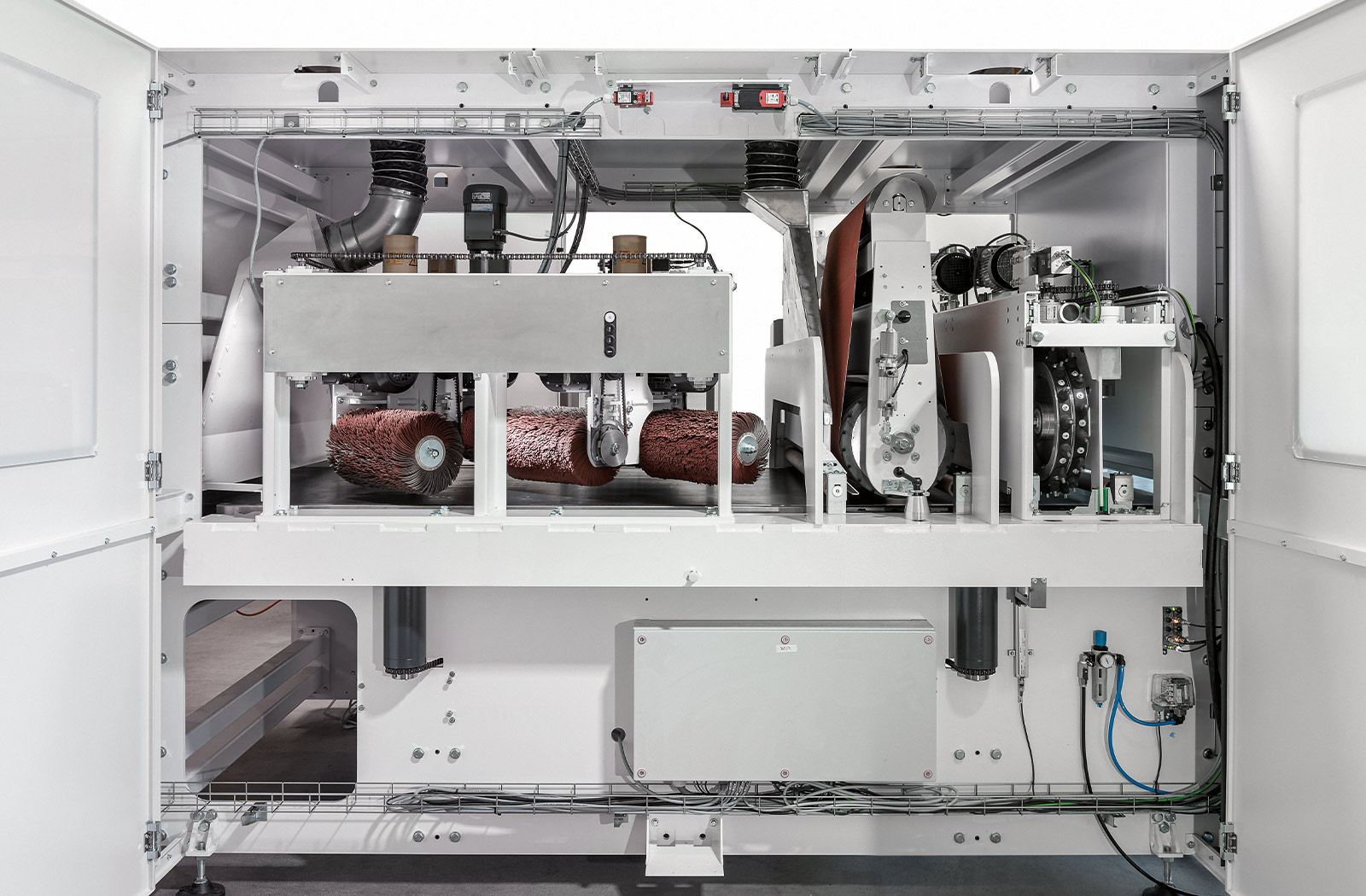

The LISSMAC – SMD3 series grinding and deburring machines score with flexibility and economy when deburring small parts. The systems of the SMD 3 P-Edition were specially designed for processing thick sheet metal and, thanks to maximum tool contact with the components, it delivers impressive performance when rounding edges up to 2 mm radius. The upstream mechanical removal of slag from plasma and oxy-fuel cut parts is effective and reduces tool costs. Thanks to our cool grinding, there is also no heat input into the workpieces.

The systems are used for deburring, quality edge rounding, slag removal, oxide layer removal and surface finishing. Plasma and flame cut parts in stainless steel, steel and aluminum as well as in non-ferrous metals can be processed. Thanks to the space-saving arrangement of the units, the grinding and deburring machines of the SMD 3 series require 30% less installation space. In addition, they can be easily integrated into automation solutions or integrated into production lines.

Technical data

Further information

- Suitable for processing various materials including steel, stainless steel and aluminium

- Simultaneous processing of different material thicknesses is possible (E-units)

- Individually adjustable processing parameters for optimum results

- The thought-out design of the rotary heads ensure an even processing result over the whole working width.

- Maximum tool contact with the workpieces for perfect edge rounding up to 2 mm radius

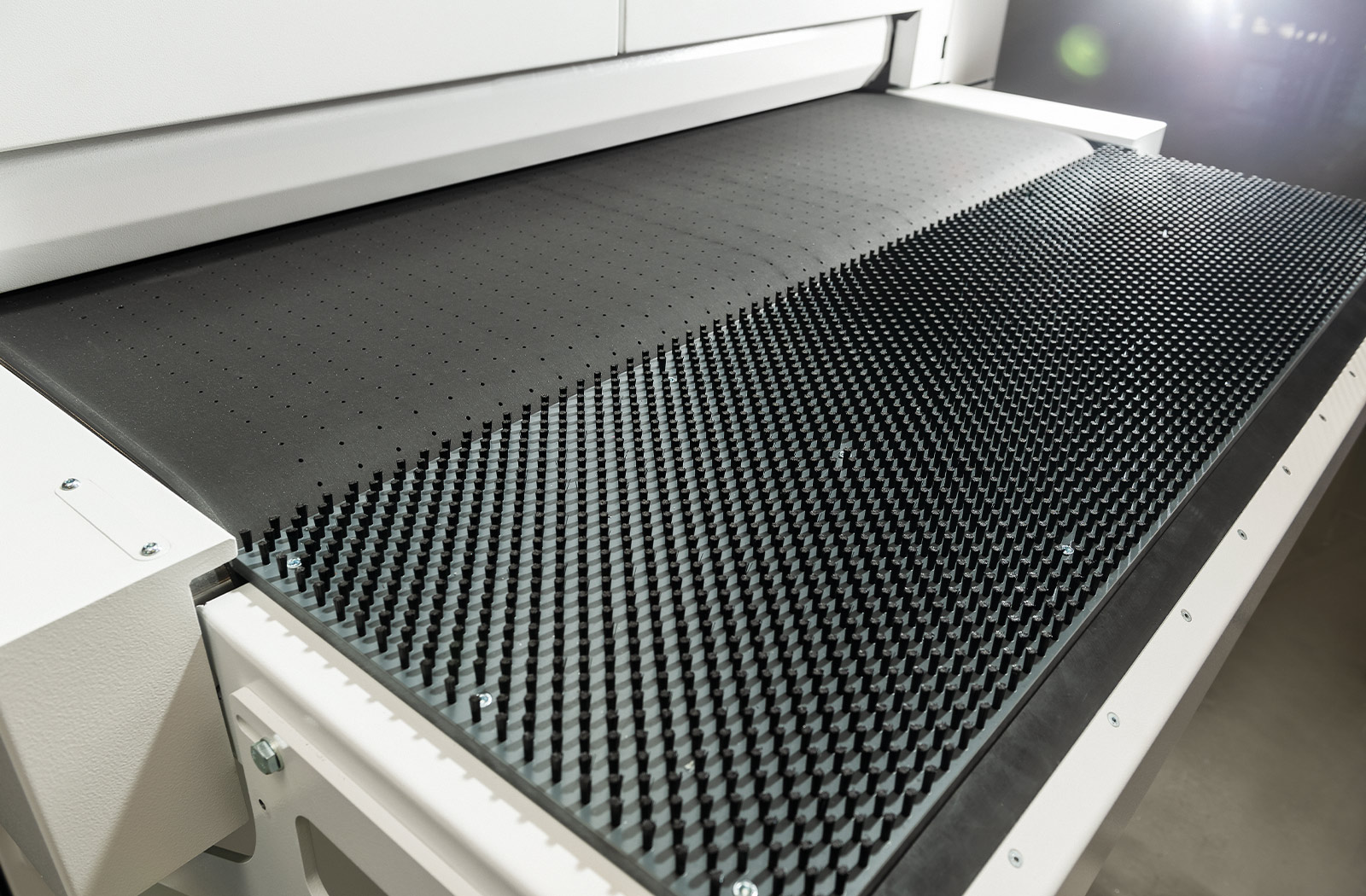

- Efficient processing of small parts (down to 50x50 mm), whatever the geometry of the pieces

- Stationary machine table - Constant table height for ergonomic work

- Intuitive operation thanks to clear touch panel

- Flexibility and energy-efficient work because the processing units can be switched on and off separately

- Fast machine setting by automatic positioning of the tool axes

- Program memory takes care of automatic machine settings and reproducible processing results

- Fast tool-changing system keeps set-up times to a minimum

- Wide range of tools for maximum flexibility

- Optimal machine accessibility facilitates cleaning and maintenance

- Window in the machine doors allows to monitor the process

- Appropriate options and features for individual customer requiremen

- Possibility of automation & integration in production lines

P-EDITION:

- Reduced tool costs by mechanical slag removal; no expensive grinding necessary

- Cool grinding - no heat entry into the workpiece

- Warpage and tolerance compensation by large, soft contact roller

- Perfect edge rounding up to 2 mm radius

- Available configurations: REE, DRE, REER, DREE

Downloads

Examples