SBM-XS G1E1

Highly effective deburring on both sides and even edge rounding for punched, laser and fine plasma cut workpieces in just one operation.

The SBM-XS G1E1 grinding machine is used for effective sheet metal processing. It was designed to process small parts as well as for processing on both sides and for a directionless finish in the field of metal processing. With this machine, LISSMAC is setting new standards with its focus on deburring and, in particular, deburring small parts. The machine also achieves significant time savings through machining on both sides simultaneously.

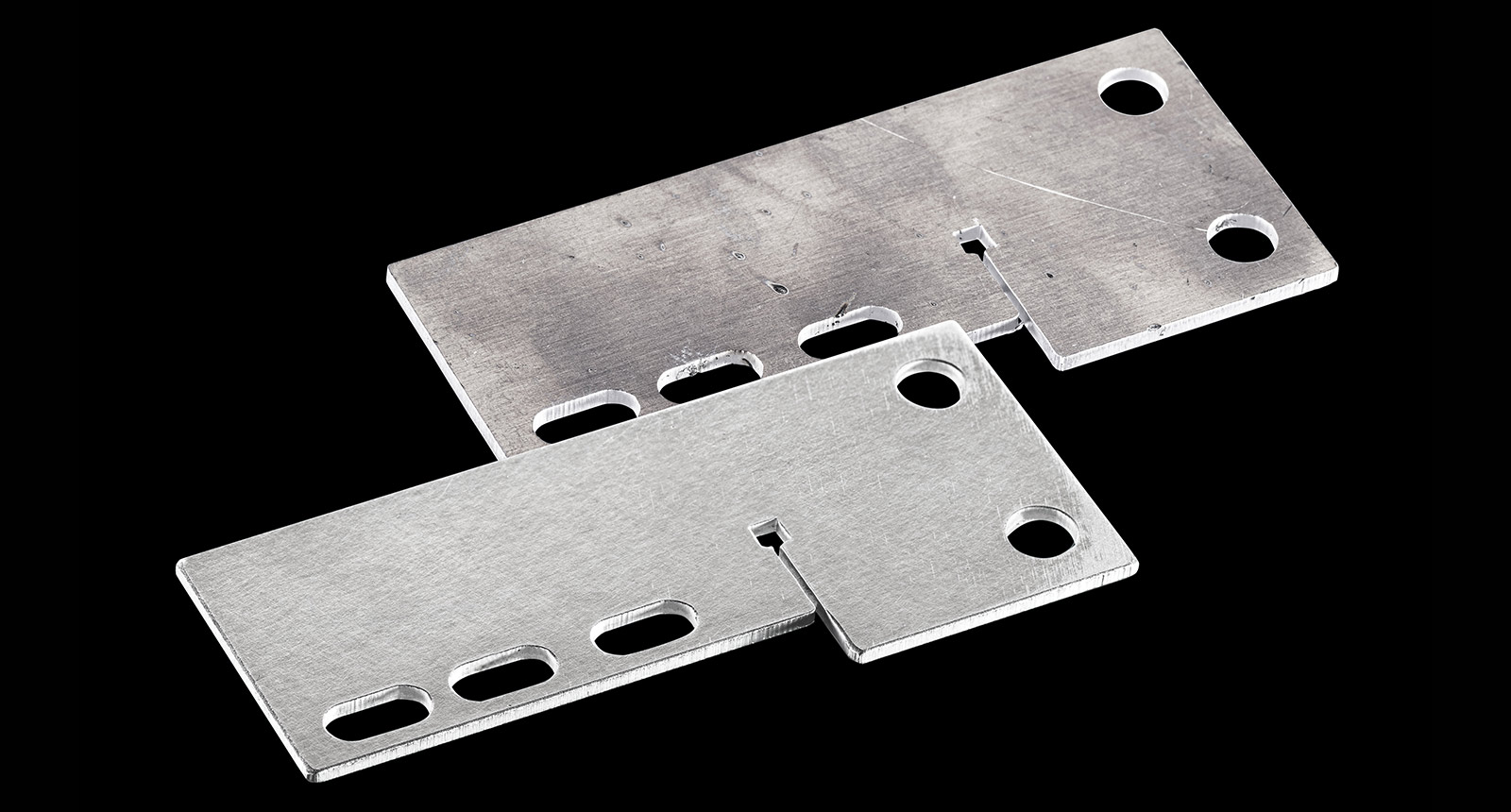

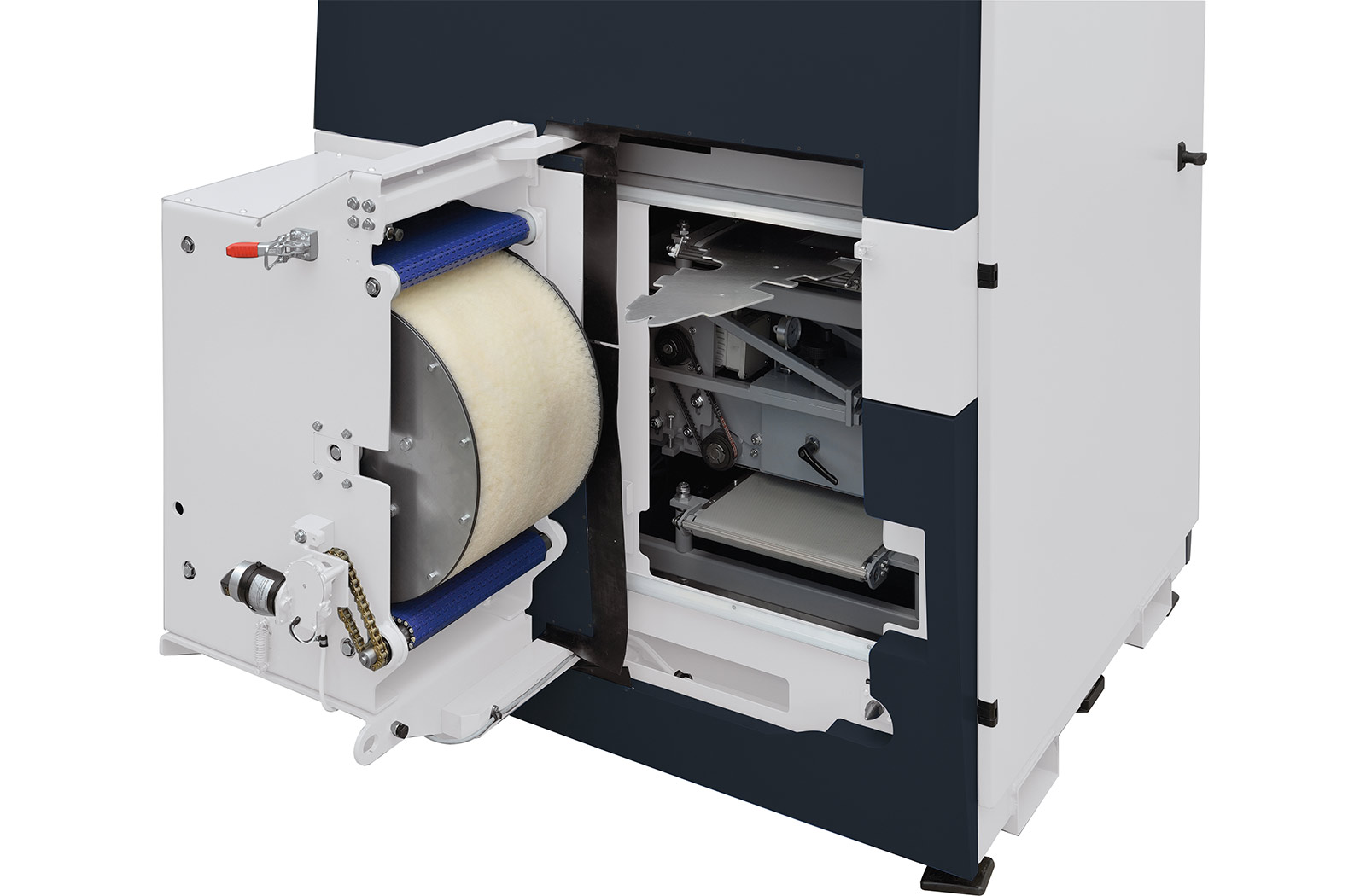

The deburring machine is suitable for deburring laser parts and rounding edges. Inner and outer contours can be machined in just one operation. When deburring, a cross-sanding belt works on the surface of the material. Burrs and surface splashes that can occur during punching or laser cutting are completely removed. All workpiece edges, on the outside and inside contours, are rounded evenly by two rotating, flexible grinding flap rollers. Secondary burrs are also effectively removed, while galvanized surfaces or protective films are not destroyed.

Technical data

(51/91/75 inch)

(51/91/75 inch)

Further information

With a magnetic table designed for part dimensions of 25 x 25 x 1 mm up to maximum 200 x 200 x15 mm (geometry-dependent)

With vacuum table for part dimensions of 45 x 45 x 1 mm up

to maximum 200 x 200 x15 mm (geometry-dependent)

- Time consuming turn-over of parts with a second pass is

not necessary - Swinging away of the innovative turning station makes it

possible to deburr parts longer than 200 mm - A higher level of automation ensures an economic and

reliable deburring process, also for large quantities of

parts - A high and sustainable deburring quality.

- Dry deburring process (no chemical additives as used in

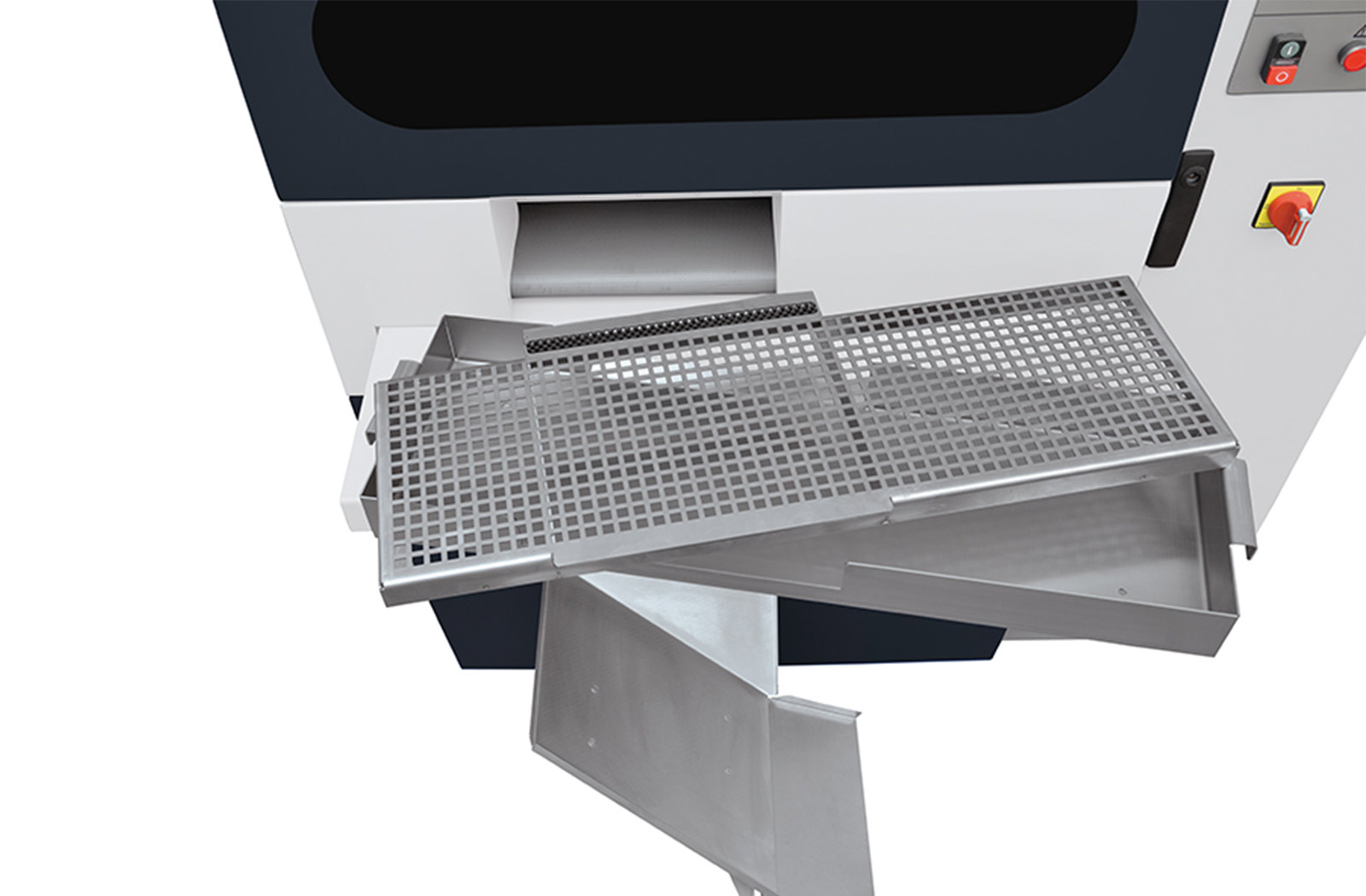

tumblers) - Small parts are returned to the front of the machine and

gathered in a box. No extra walking back and forth for

the operator. - Energy-efficient

- The deburring process ensures an even wear of the belt

and brushes across the entire width of the machine - Fast and simple tool Change

- Simple and intuitive operation of the machine

- Modern, compact machine design

Downloads

Examples