SBM-M S2

The deburring machine can be used for flexible edge rounding, as well as for deburring laser parts or for processing punched parts.

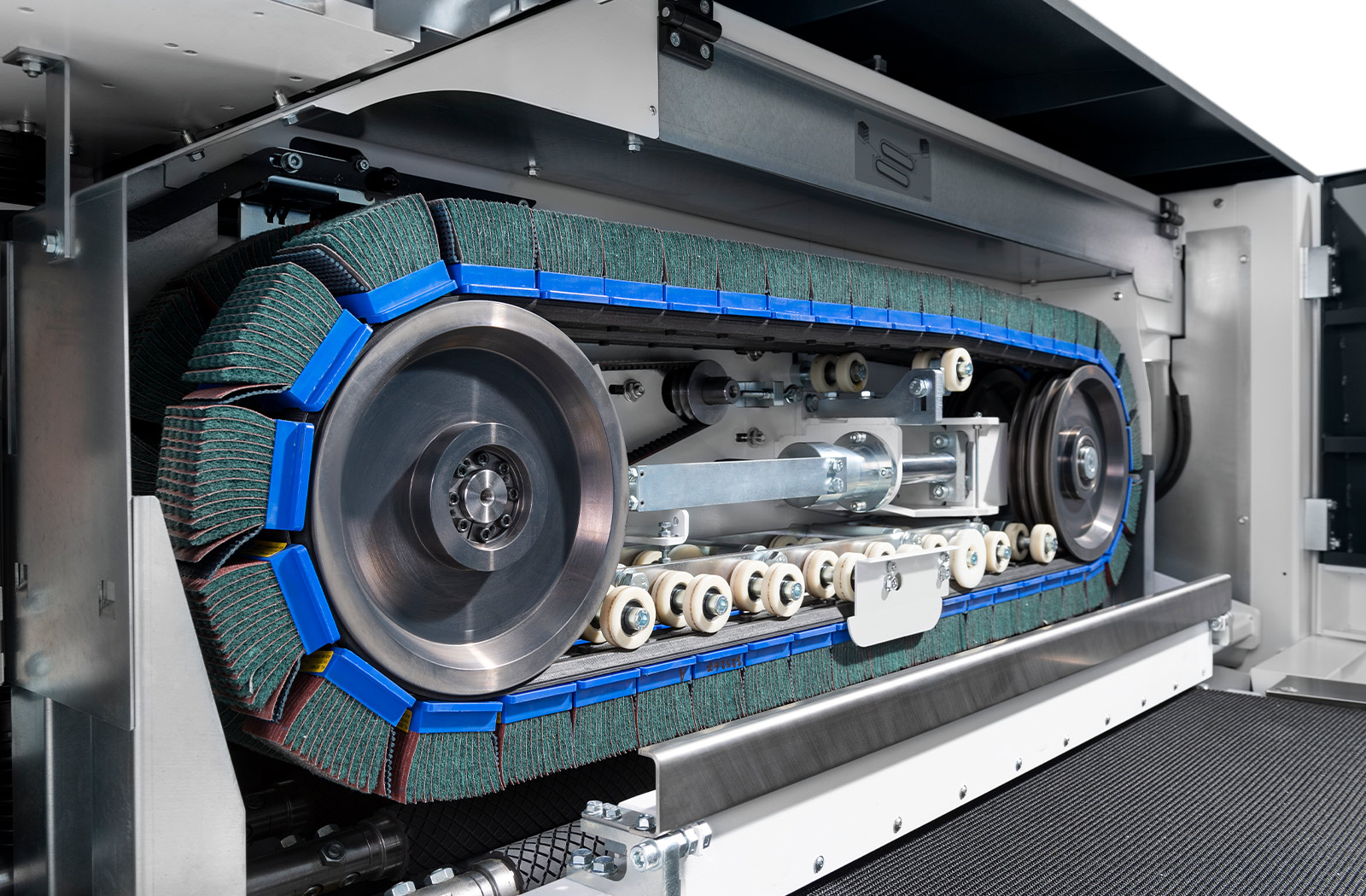

The SBM-M S2 grinding machine was developed for processing sheet metal and laser parts on both sides. Edge rounding of inner and outer contours on both sides in one operation ensures process efficiency. Machining on both sides simultaneously can save up to 60% in time.

The deburring machine can be used for flexible edge rounding as well as for deburring laser and punched parts. The machine deburrs the sheet metal parts to achieve the highest possible quality for further processing or finishing. Deburring of stainless steel, steel and aluminum can be carried out. Non-ferrous metals can also be processed. In addition, the SBM-M S2 from LISSMAC is suitable for processing foiled sheet metal.

Technical data

3300/1400/1800 mm

(111/56/71 inch)

3300/1400/1800 mm

(130/56/71 Inch)

Further information

- Deburring and edge rounding of sheet and plate up to 50 mm material thickness

- No need to turn sheets over and running them through the machine again

- Up to 60 % work time savings compared to one-side processing grinding machines

- Highest quality during subsequent processing or finishing

- Simultaneous edge rounding of interior and exterior contours

- The cross-machining principle guarantees uniform tool utilisation over the entire working width.

- Protective foil on the sheets is not damaged during machining

- Dry operation

- Simple, intuitive operation

- Each tool unit can be separately electrically operated and adjusted

- Hydraulic belt tension – fast tool change within only a few minutes

- Modular and compact in modern machine design - smaller footprint

- Improved work environment - Reduction of dust, dirt and noise

- Optionally available: Conveyor Technology; Handling Systems, Automation; Custom Solutions

Downloads

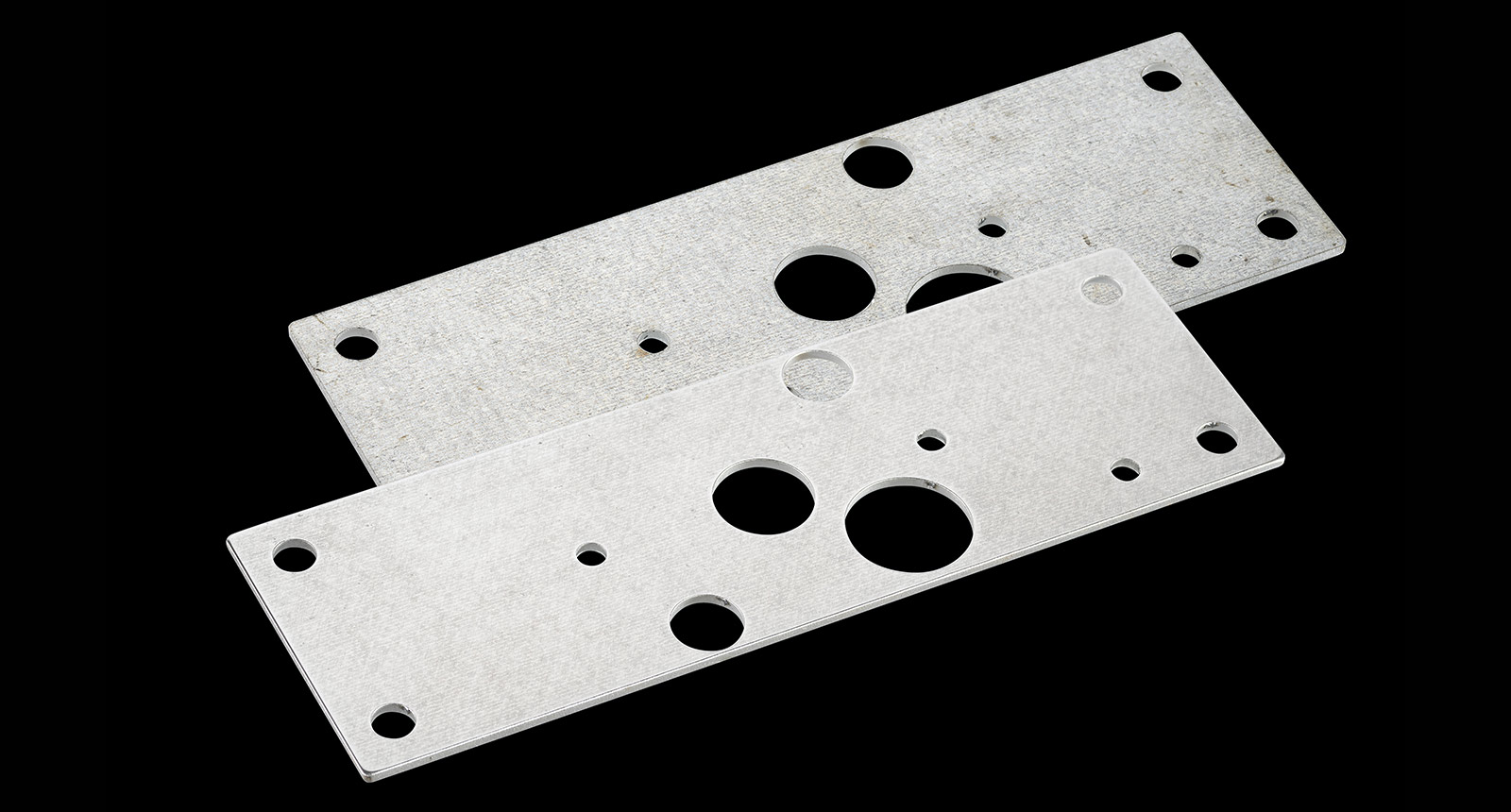

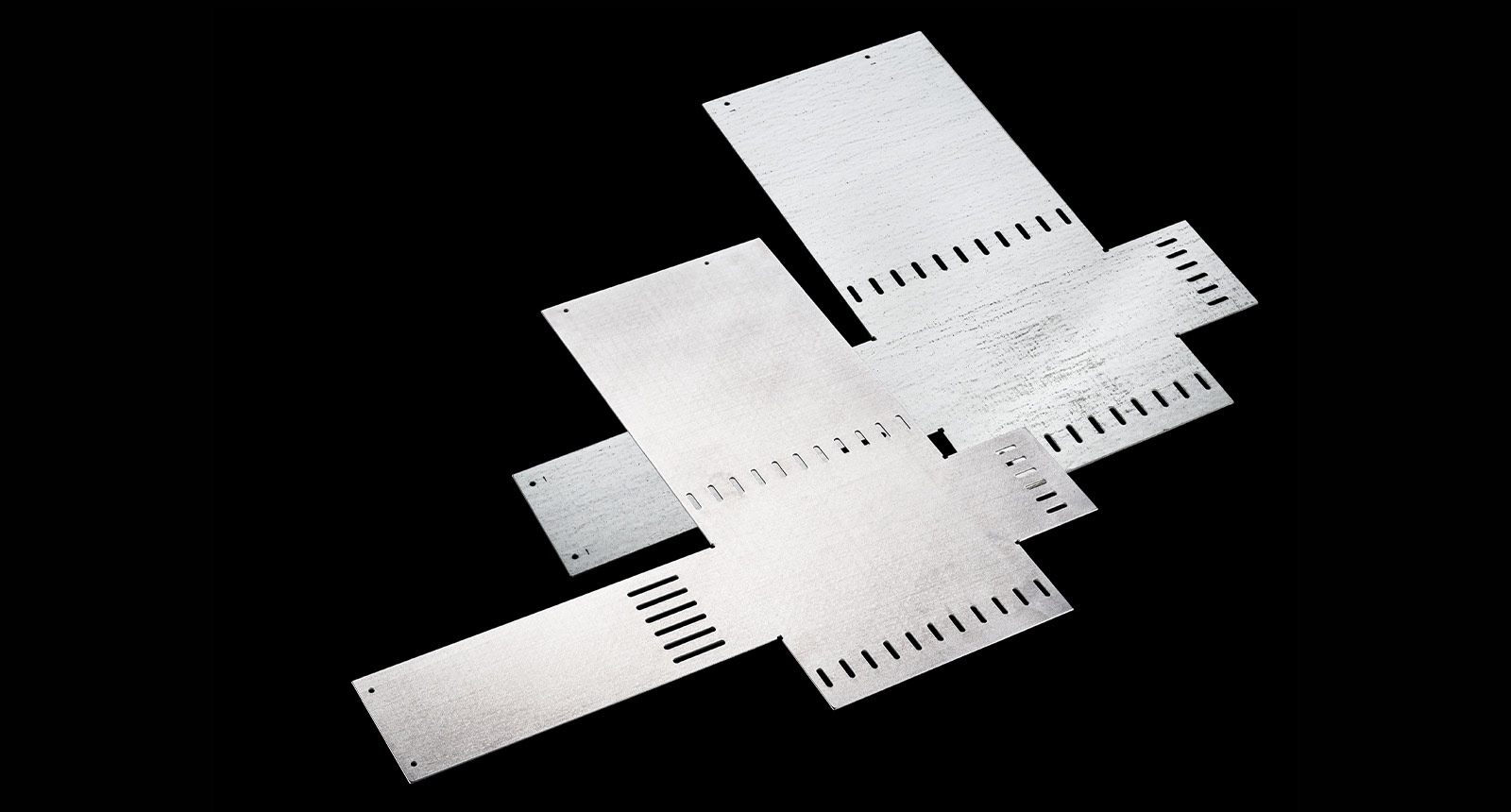

Examples