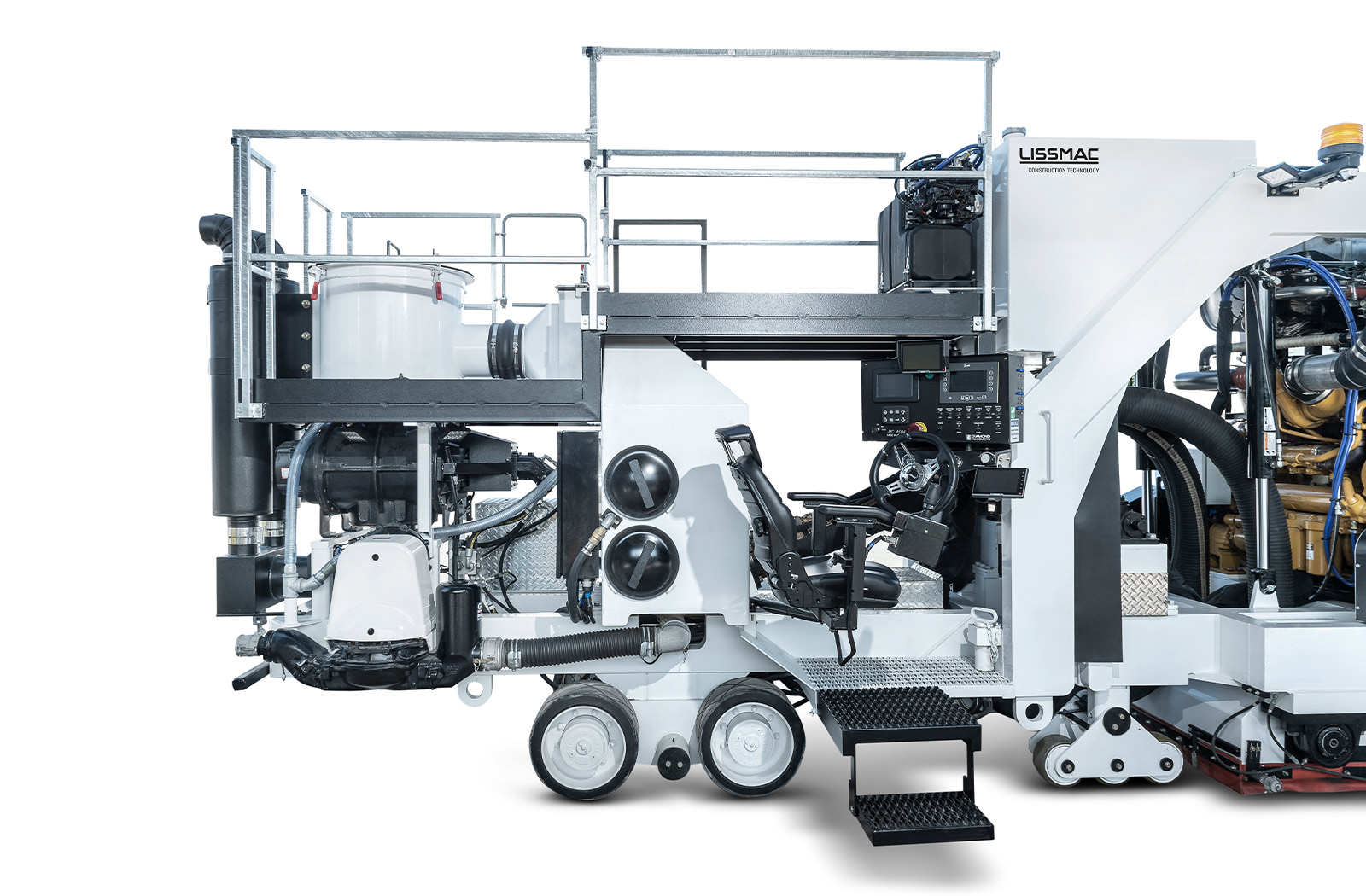

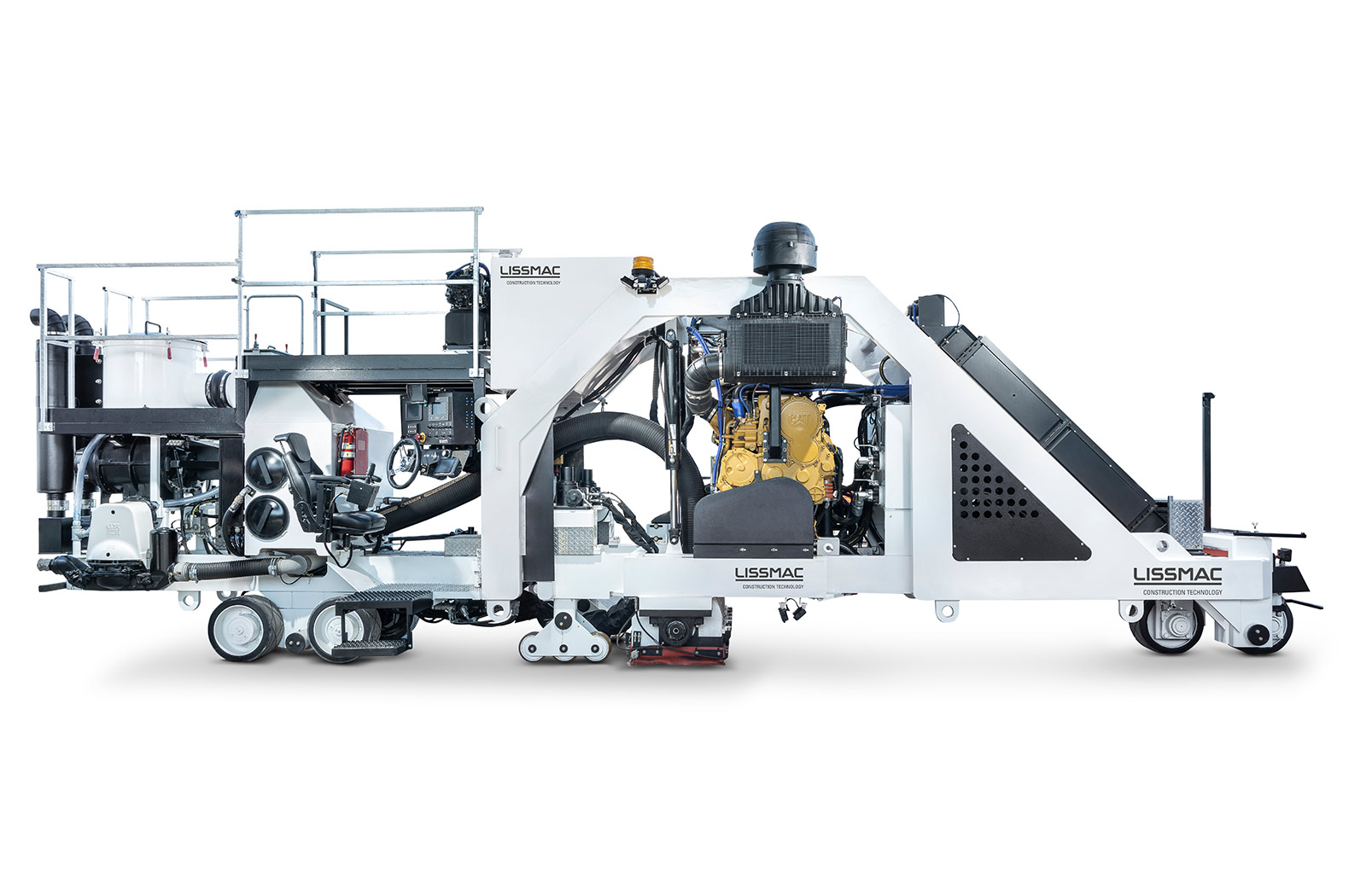

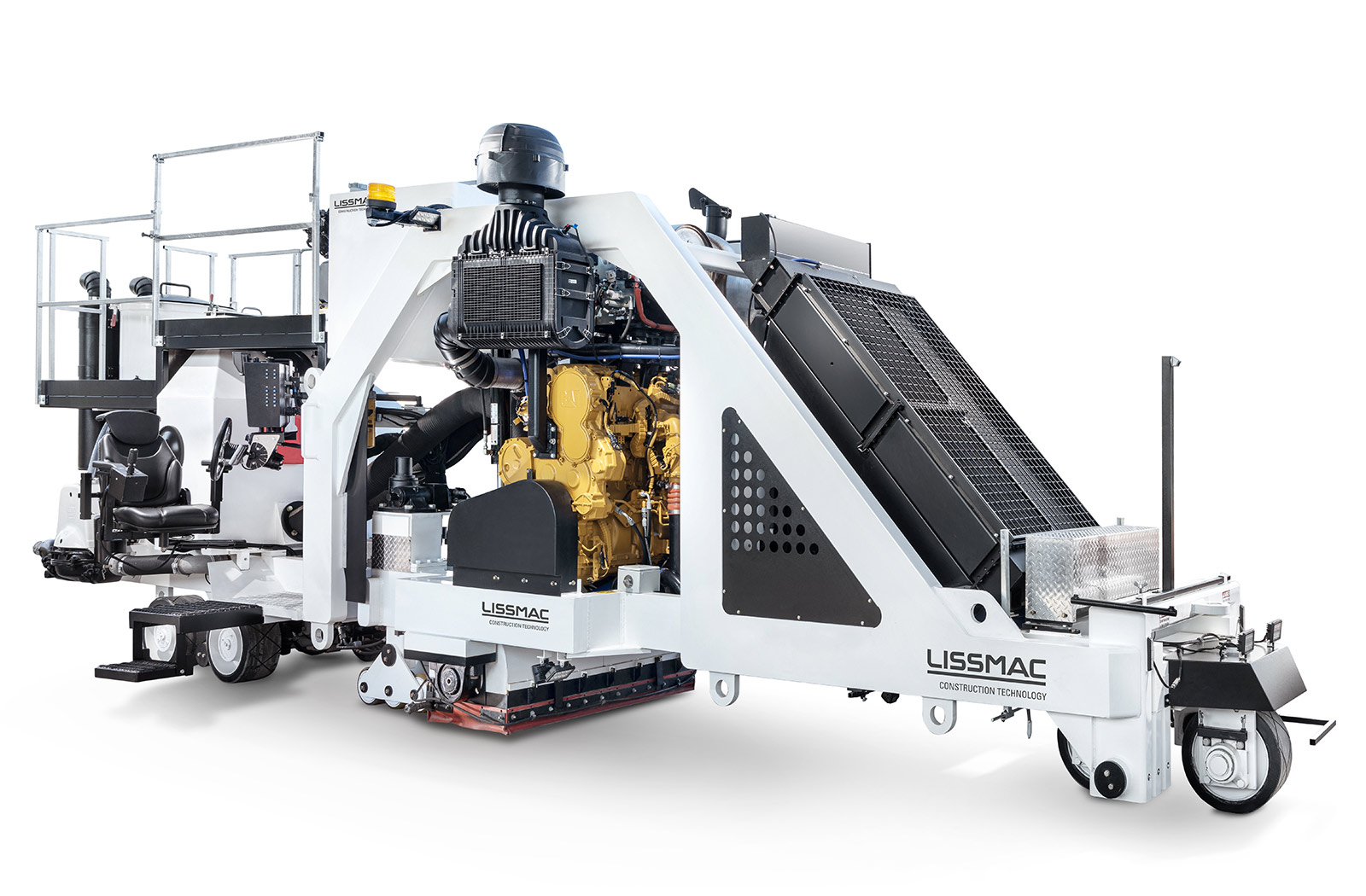

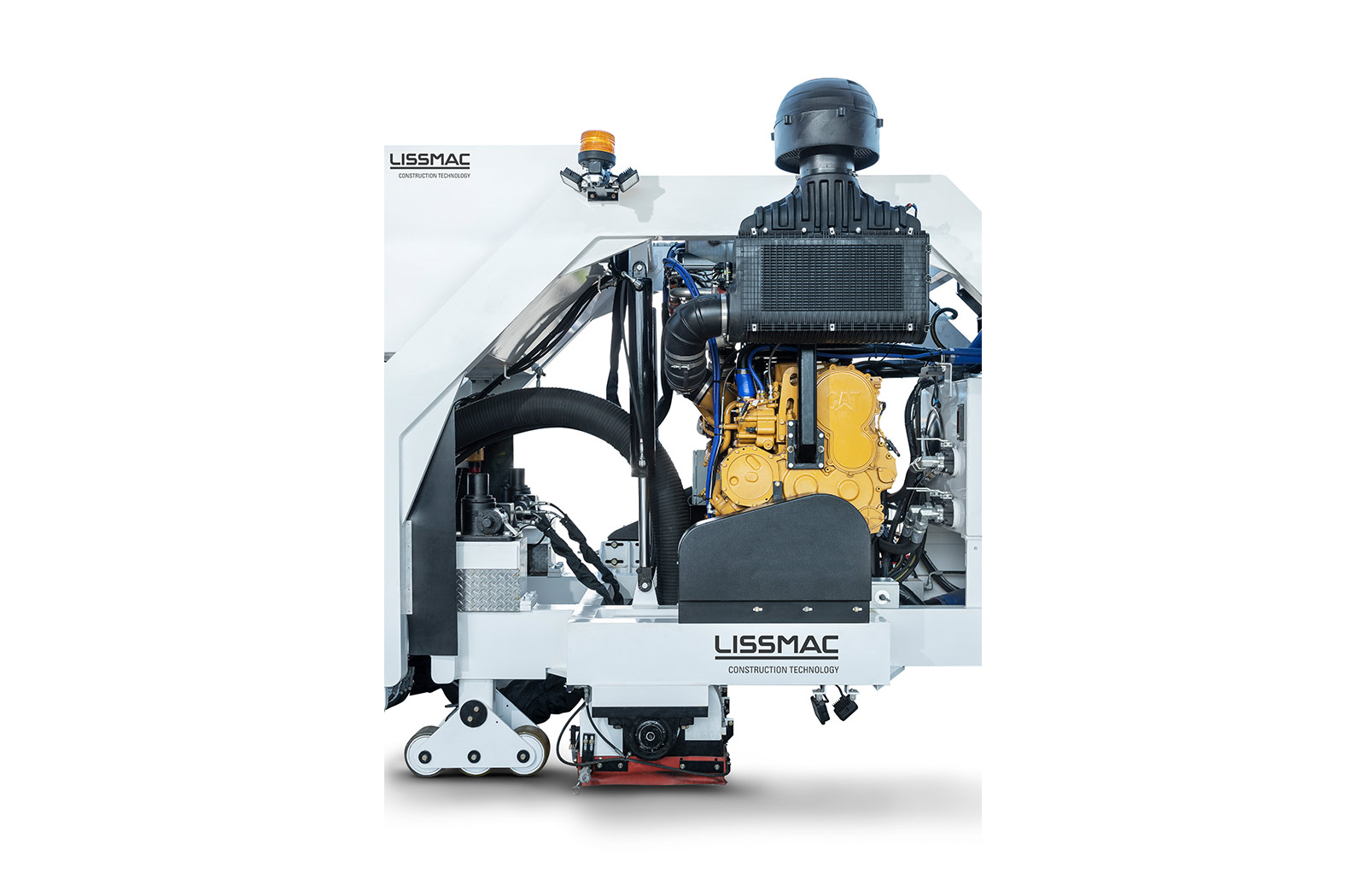

Bump Grinder

Powerful machine - ideal for the surface treatment of roads and airport runways.

Contact salesTechnical data

Further information

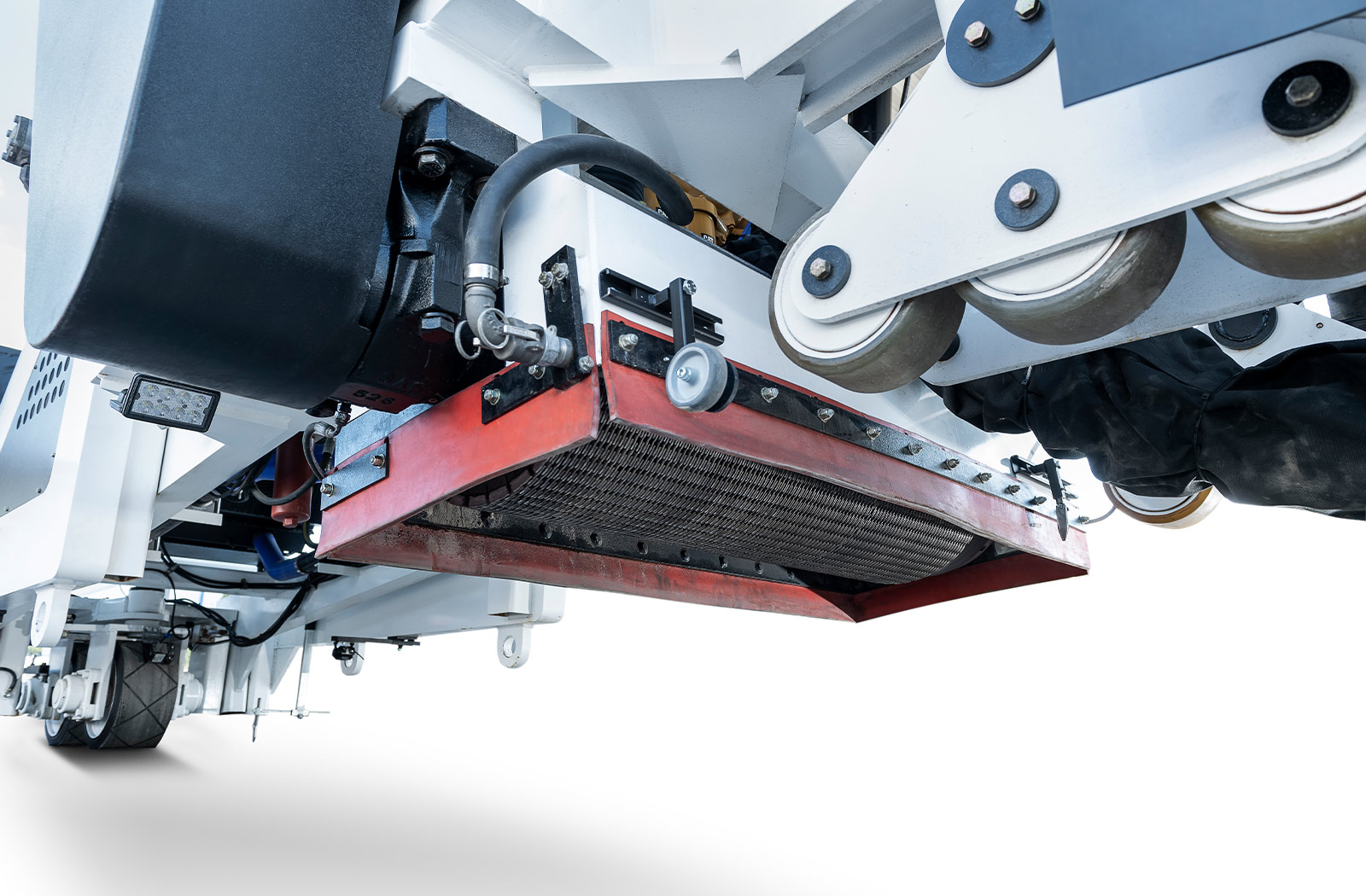

Grinding

Surface grinding serves to produce a well-defined roughness to guarantee optimum road grip for vehicles. Another

application of the process is acoustic grinding. This involves selecting a cutting shaft which will yield a corrugation

pattern to help reduce road noise.

Grooving

The cutting of corrugated profiles for the purpose of draining water away from road surfaces is called grooving. This

process is not exclusive to road traffic surfaces, but is also used on aviation traffic surfaces. In addition to improving

water drainage, it increases the surface area of the road and thereby allows it to dry faster.

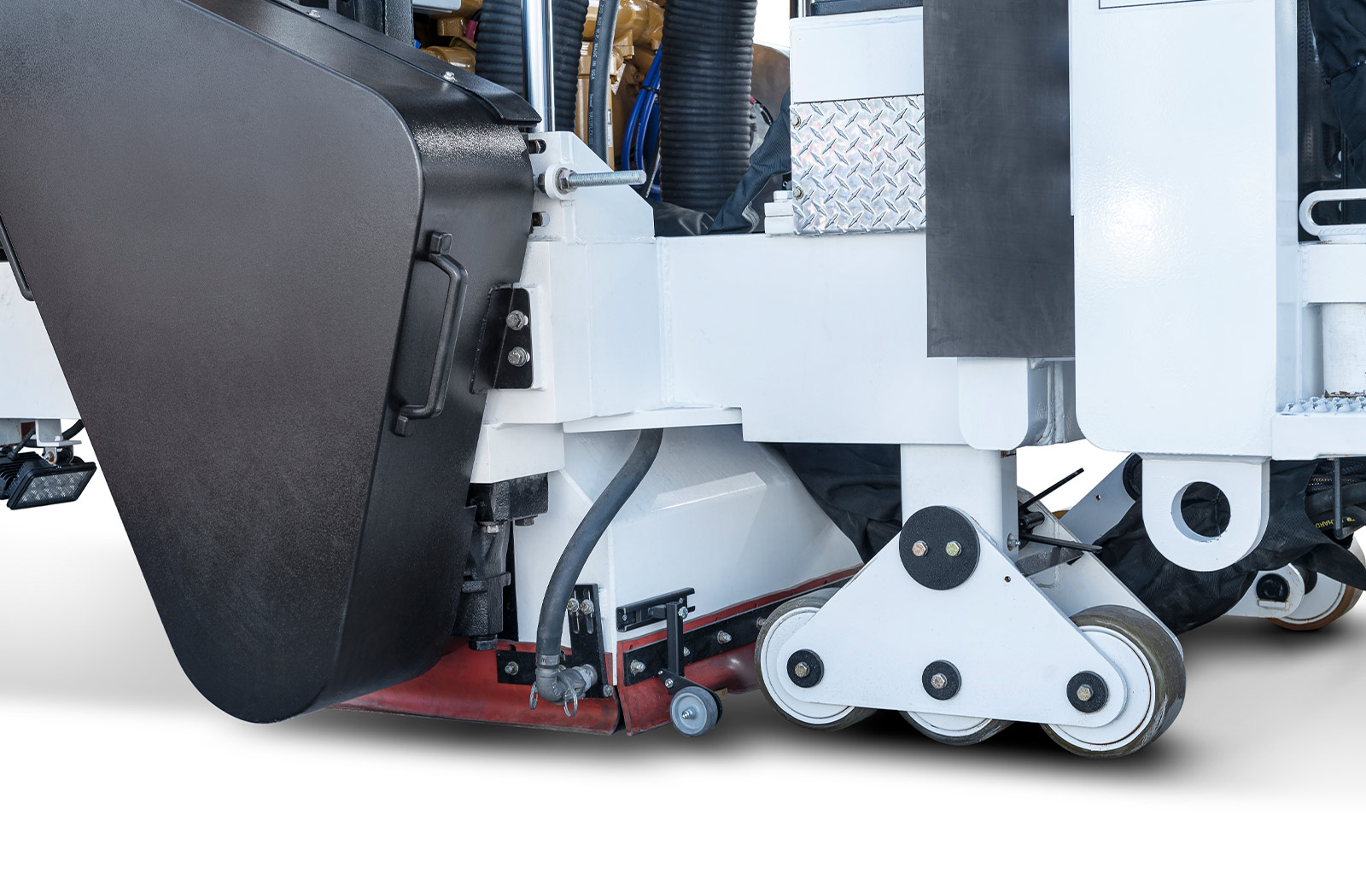

Bump Cutting

Plane surface grinding is also referred to as bump cutting. This smooths out any unevenness that may occur during

the manufacturing process or as a result of surface wear. By reducing the grinding shaft amplitude, the process can

also be applied to smooth out small height differences (edges) between surfaces.

- Designed for continuous grinding projects or bump grinding

- Can be operated manually or with computer controlled cruise control system that automatically adjusts forward speed to cutting conditions

- Equipped with odometer that measures total footage (meters) ground and has a resettable daily production odometer and feet (meters) per minute indicator

- On board slurry vacuum and discharge system

- Hydraulically controlled depth control wheels

- Depth control wheels are side to side adjustable for accurate cut matching

- Safe ascent due to slip-proof access ladder

- Wide and non-slip catwalk on the machine

- High railing ensures a high level of safety

- Comfort seat with integrated safety switch and connected acoustic warning system

- Excellent all-round view thanks to 4x camera system (Bird-View) including large colour

- Available in two grinding width (1270mm / 1400 mm)display