BevelPro Type FF

BevelPro Type FF

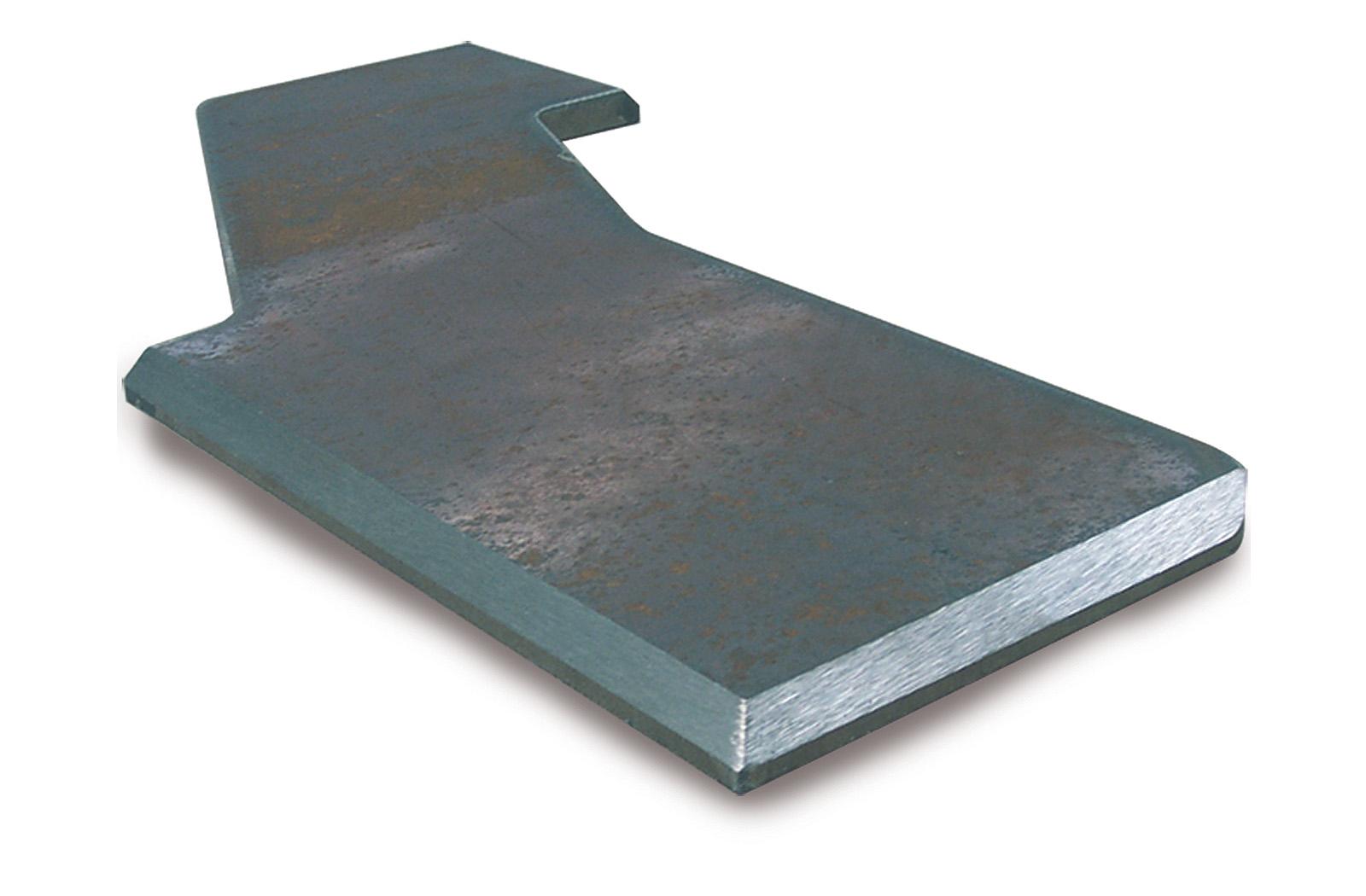

The belt grinding machine for grinding edges and bevels for weld seam preparation without critical heat influence on the material.

The BevelPro Type FF is designed for the high requirements of weld seam preparation without any critical heat influence on the material / edges. The simple machine concept, with two different table sizes, can be used for grinding and beveling of single side bevels and edges.

The high-performance belt grinding process meets all requirements of precision bevels and strips, a clean and metallic-blank seam surfaces and minimal heat influence.

Contacto distribuciónDatos técnicos

BevelPro Type 3.1

Sideframe

Closed

Table sizes

1500 mm / 3000 mm

Motor power

9,2 kW

Material removal rate

Up to 80 cm³/min

Grinding belt speed

Up to 32 m/s

Bevel angle

0° - 60°

Feedrate grinding unit

Up to 5 m/min

Machine control

Siemens S7

BevelPro Type 4.1

Sideframe

Open

Table sizes

1500 mm / 3000 mm / 4000 mm

Motor power

9,2 kW

Material removal rate

Up to 80 cm³/min

Grinding belt speed

Up to 32 m/s

Bevel angle

0° - 60°

Feedrate grinding unit

Up to 5 m/min

Machine control

Siemens S7

Información adicional

- Savings of approx. 40% of machining time by higher motor power and material removal rate in comparison to milling or roughing lathes

- Significant less investment and production costs then Milling lathes or plasma cutter

- With a ceramic corn grinding belt a high removal rate with constant quality can be reached. (up to 7 times compared to conventional grinding belts). There is only very low heat influence on the material surface, ensuring a homogenous grinding result withou the need for further processing.

- The grinding belt reaches a speed up to 32 m/s

- By using the very rigid table surface and movable stop-units the workpieces can be easily and repeatable positioned. The downtime for setup will be reduced to a minimum

- Very good access from the front side

- Controls S7 with OP-Panel is easily and safe to use from operator

- All Parameters, like dimensions, speeds, pressure, removal profiles, overlapping etc. are easy to program and setup

- Integrated calculation tool for easy programming: input of bevel angle and depth, length and material is enough to produce a new program

- Quick change of grinding belt within a minute by self-centering of belts

- High reliability of grinding belts by automated oscillation

BEVELPRO TYPE 3.1 vs. BEVELPRO TYPE 4.1: THE DIFFERENCES

- BevelPro Type 3.1 has a closed sideframe. No movement through the working area for longer workpieces possible

- BevelPro Type 3.1 offers the ideal price-performace-ration, thus is a perfect entry-level machine

- BevelPro Type 4.1 has an open sideframe

- Movement through the working area for longer workpieces possible.

Descargas

Exemples