Diamond trenching following DIN 18220

Diamond trenching as an alternative laying method

The term diamond trenching describes a process for laying pipes for fiber optic infrastructure in which narrow trenches and slits are created using diamond grinding technology, preferably in asphalt, but also in other compacted soils. The fiber optic media (cables and/or empty conduits) are then laid and the trench is sealed securely and flush with a liquid filler and a layer of bitumen.

This laying method is of central importance for fiber optic expansion, as it takes up very little space and enables empty conduits and fiber optic routes to be completed quickly. Compared to traditional civil engineering, there is no need for open construction with heavy equipment and large trenches.

DIN 18220 comes into force

On 28.07.2023, "DIN 18220:2023-08. trenching, milling and plowing methods for laying empty conduit infrastructures and fiber optic cables for telecommunications networks" was adopted. The document was officially presented at an event on the gigabit strategy of the Federal Ministry for Digital and Transport (BMDV). According to Section 126 of the German Telecommunications Act (TKG), it is to be applied uniformly by all parties involved as a recognized technical rule from the time of publication.

DIN 18220 is intended to contribute to the cost-effective acceleration and, above all, high-quality implementation of fiber optic expansion. It defines clear conditions for deployment and execution and sets the legal framework for achieving a milestone in broadband and fiber optic expansion.DIN 18220 increases investment security for all parties involved, especially for telecommunications companies.

What the new DIN 18220 changes

Up to now, most local authorities have mainly chosen the open construction method as the laying method for fiber optic expansion, as the minimum overlap had to be at least 60 cm before the standard was introduced. DIN 18220 now regulates laying methods for reduced construction depths, including diamond trenching from LISSMAC (38 cm laying depth).

"With DIN 18220, fiber optic installation will not only be easier in the future, but also of higher quality, faster, more cost-effective and more resource-efficient.DIN 18220 creates the necessary legal certainty and investment security for all parties involved," said BMDV State Secretary Stefan Schnorr, describing the importance of the new standard.

What DIN 18220 means for LISSMAC

LISSMAC has been active in diamond trenching for around 10 years.Due to our experience in the field of joint cutting, we are a long-standing member of the VDMA (German Engineering Federation) and were involved in the creation of the standard as a member of the standardization committee. We are very pleased about the recognition of the alternative laying methods for fiber optic expansion, including LISSMAC diamond trenching, as the standard creates clarity for the construction industry, all municipalities, local authorities and telecommunications companies.Trenching with diamonds: how diamond trenching works

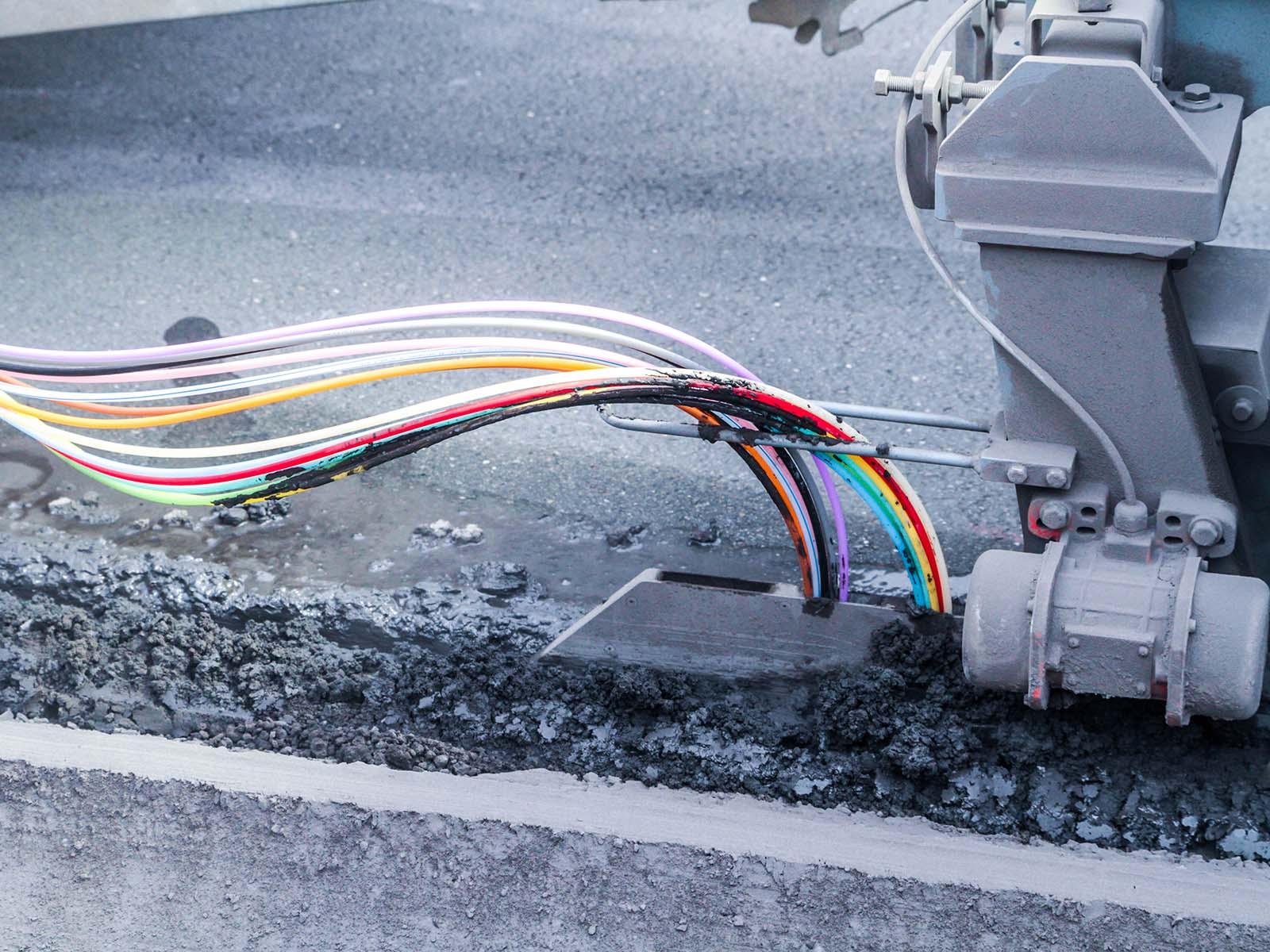

Diamond trenching is characterized by the fact that we create the trench with diamond saw blades. The diamond trenching blades specially developed for the process cut or grind all obstacles and materials that are built into the substrate.The advantage is a monotonous, very even cut that leaves straight walls. This simplifies the backfilling and sealing process and is also very cost-effective due to the narrow cutting width.

Our many years of strong performance make us the leading manufacturer of trenching machines with the best distribution channels and the best technology.

With a production capacity of at least 1 m/min, our DT 610 diamond trenching machine enables both the trenching of the top layer (asphalt) and base course and the simultaneous laying of a large number of individual pipes at the bottom of the trench using a laying unit developed for this purpose. During operation, the hydraulically operated laying unit, also known as the plow, is folded downwards, immediately following the diamond saw blade.This not only guides the empty pipes into the joint, but also prevents the joint walls from collapsing.

Our machines can be used to "cut" in various ways:

- Straight Cut with the DT 610: Long cuts with our 136 hp UNICUT 610 as the carrier machine

- Cross Cut with the DT 90: Roadway crossings or branches for house connections with our MULTICUT 905 with 75 HP as the carrier machine

ADVANTAGES of trenching, milling and plowing methods

- Efficiency: LISSMAC trenching is a fast and efficient laying method.300-500 m of empty conduits for fiber optics can be laid per day - including compaction!In comparison: With the open construction method, just half of this can be achieved.

- Flexibility: Diamond trenching is preferably used for asphalt, but can be used almost anywhere where the substrate is well compacted.The space-saving laying method is particularly popular in densely populated areas and on highly frequented traffic routes.As the minimal cut can be driven over, no temporary bridges are necessary and the passage is clear again after a few minutes.

- Quality: The problem with the open construction method is that it is often not implemented to a high standard. For example, poor compaction can lead to the filling material sinking, resulting in expensive complaints. Trenching guarantees high-quality implementation.

Criticism of trenching, milling and plowing methods

Of course, diamond trenching can and should also be viewed critically.It should be noted that this laying method cannot be used everywhere.For example, paved stretches still have to be processed using the open construction method, as no cutting is possible here. In some cases, diamond trenching is also not always necessary. This is conceivable, for example, on rural roads that do not need to be opened up, as the fiber optic media can be laid next to the road in the verge or on the green area.

From a holistic perspective, however, trenching, milling and ploughing methods are indispensable for accelerating fiber optic expansion.

Diamond trenching in action

Downloads

Your contact sales for

diamondtrenching with DIN 18220

Holger Sandt

Area Sales Manager

+49 (151) 24503200

j.ucpfv@nkuuoce.eqo

Experts in fiber optic infrastructure: LISSMAC and NEXTEC System AB

The system consists of:

- Conventional ducts and infrastructure studies

- Determination of duct depth with the help of GPR on demand

- Trenching with diamond blades and duct installation

- Filling the trench with Nextec- inject

- Permanent reinstatement of the road surface

For further information please visit