The perfect solution for every customer requirement

SBM-XS G1E1

Double sided deburring of small parts - Deburring and uniform edge rounding on all sides of parts, both on outer- and inner contours, in a single pass

SBM-M B2

Oxide removal of laser cut sheet metal on both sides in one single pass

SBM-M S2

Deburring and edge rounding of steel and stainless steel on both sides in one single pass

SBM-M D2

Slag removal of plasma and oxy fuel cut parts on both sides in one single pass

SBM-L G1S2

Deburring machine for grinding, deburring and edge rounding of punched, laser and high definition plasma cut parts in one single pass

SBM-XL G2S2

Deburring and edge rounding of laser, plasma and oxy fuel cut parts on both sides in one single pass

SBM-XL S2B2

Edge rounding and oxide removal on laser cut parts on both sides in one single pass

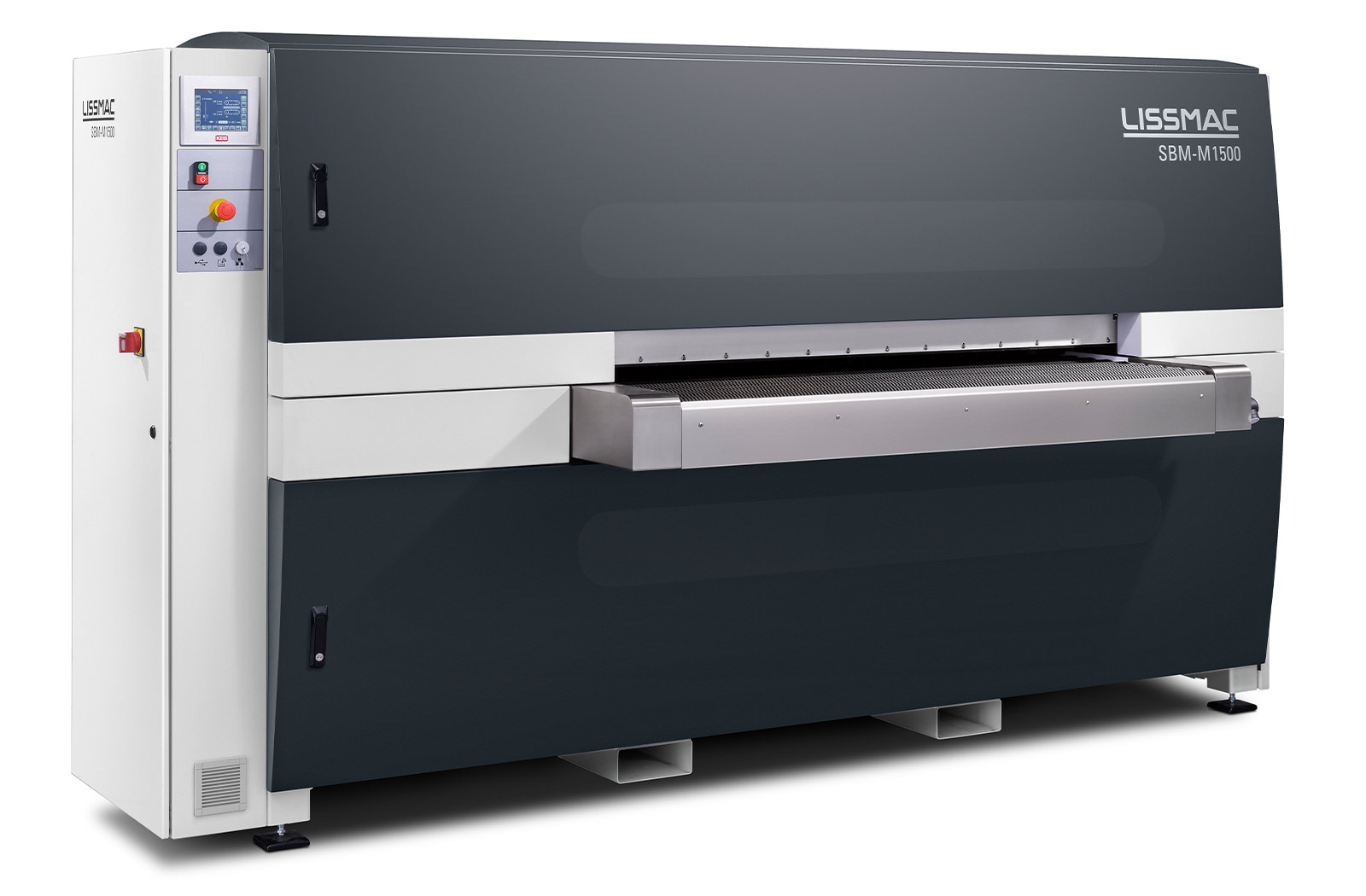

SMD 123 RE

Dry grinding machine for deburring, consistent edge rounding and surface finishing

SMD 133 DRE

Economical removal of slag, deburring and edge rounding on plasma- and oxy-fuel cut parts

SMD 3 S - EDITION

Outstanding results on the edge and on surface

SMD 3 P - EDITION

Highest-end edge rounding

SMD 5

Grinding machine in dry execution for the perfect surface finish

SMW 5

Grinding machine in wet execution for the perfect surface finish

Transport belts / Roller conveyors

Optimally adjusted to LISSMAC grinding and deburring machines

Dust extractions

Optimally adjusted to LISSMAC grinding and deburring machines

EBSC

For small parts | The entry-level machine

DBS

For rough and fine grinding | The preconfigured machine

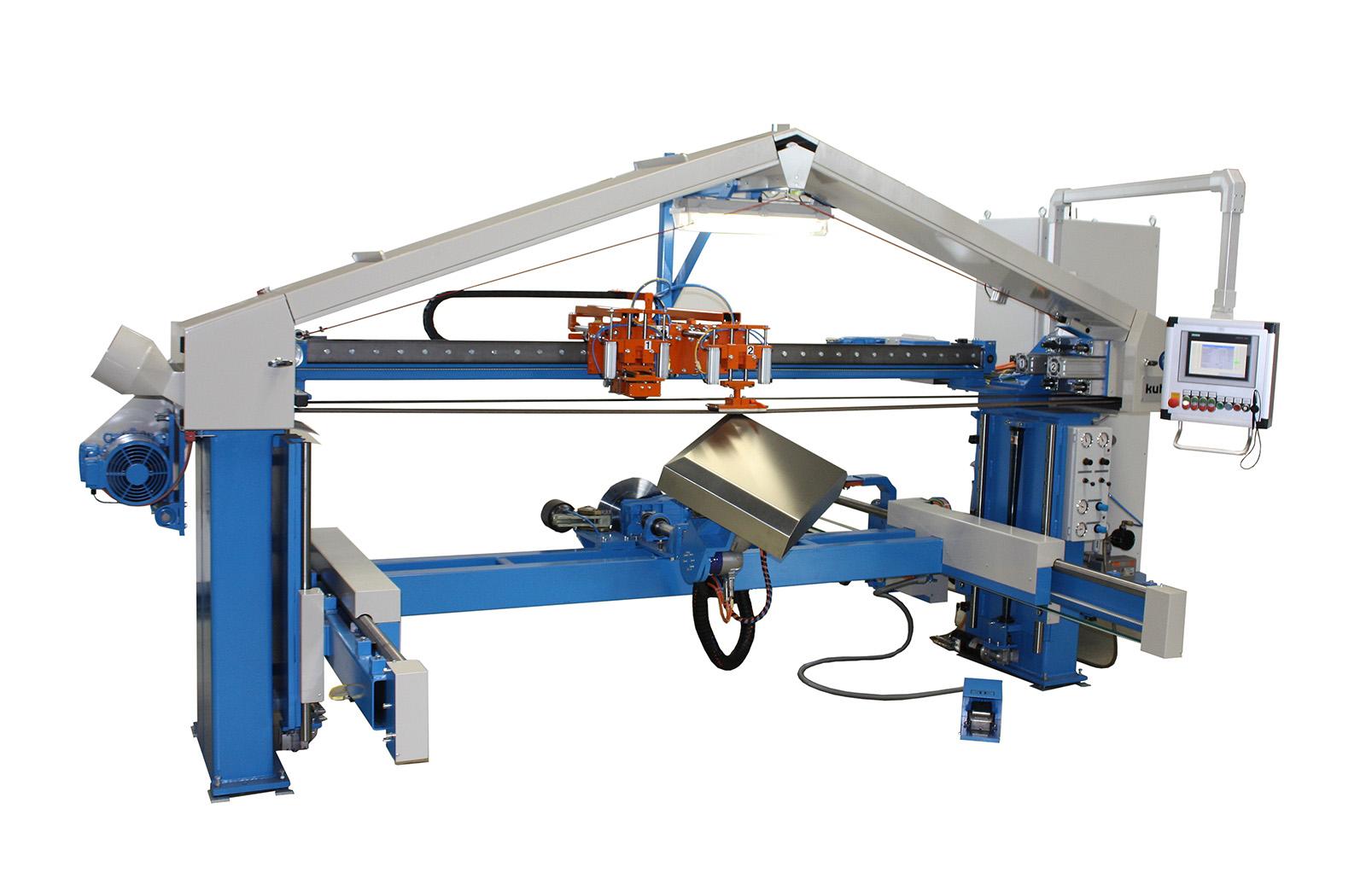

ZBS

Grinding of welded edges, contours and surfaces | Fully configurable machine

BevelPro Type FF

Grinding of welded edges, contours and surfaces | For standard edge beveling

UKF

Grinding of welded edges, contours and surfaces | For heavy edge beveling

Sorry, your search did not return any results.

The selected segment is not available in your region.

Please contact our sales team for further information.